Basic Compact MX

High ionic removal, Compact and Plug-and-play

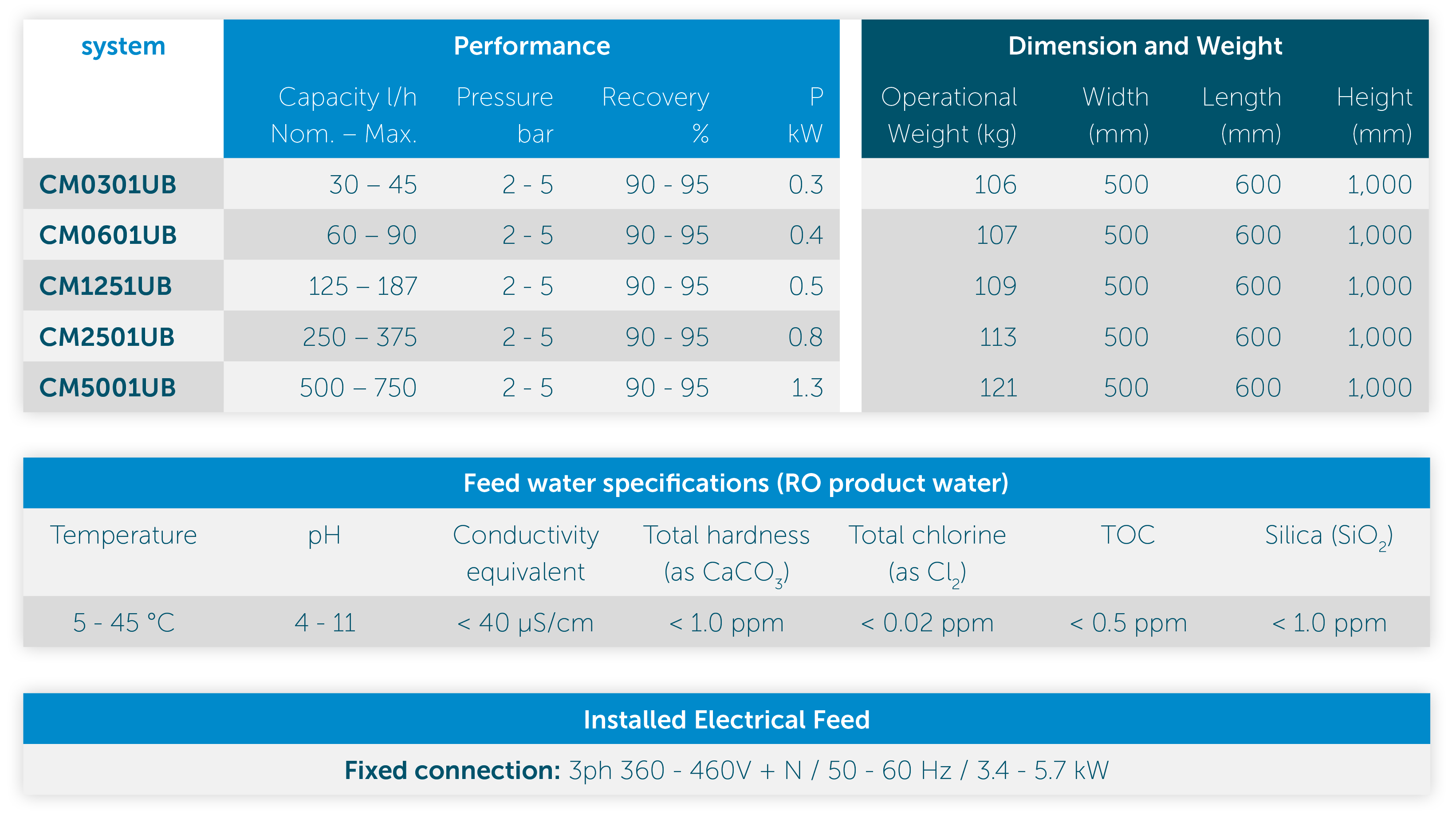

Our Basic Compact Continuous Electrodeionization (CEDI) systems based on the MX module are designed and manufactured to further purify reverse osmosis product water to ultra pure or high purity water (0.055 – 0.5 µS/cm). These pre-engineered and ready-to-run CEDI

systems are fully factory acceptance tested to significantly reduce installation and start-up costs and are available in a range from 15 to 750 l/h. The outstanding design and use of Ionpure’s® patented continuous electrodeionization technology ensures high reliability,

minimizes maintenance and eliminates use of regeneration chemicals.

Technology

How it works.

The water passing through the product compartments is deionized to pure water, while the rest of the water is flowing into the reject compartments. This water takes away concentrated salts and small amounts of gases formed on the electrode surfaces. The reject water exiting the CEDI system is typically re-used and mixed with the RO feed water in a vented break tank.

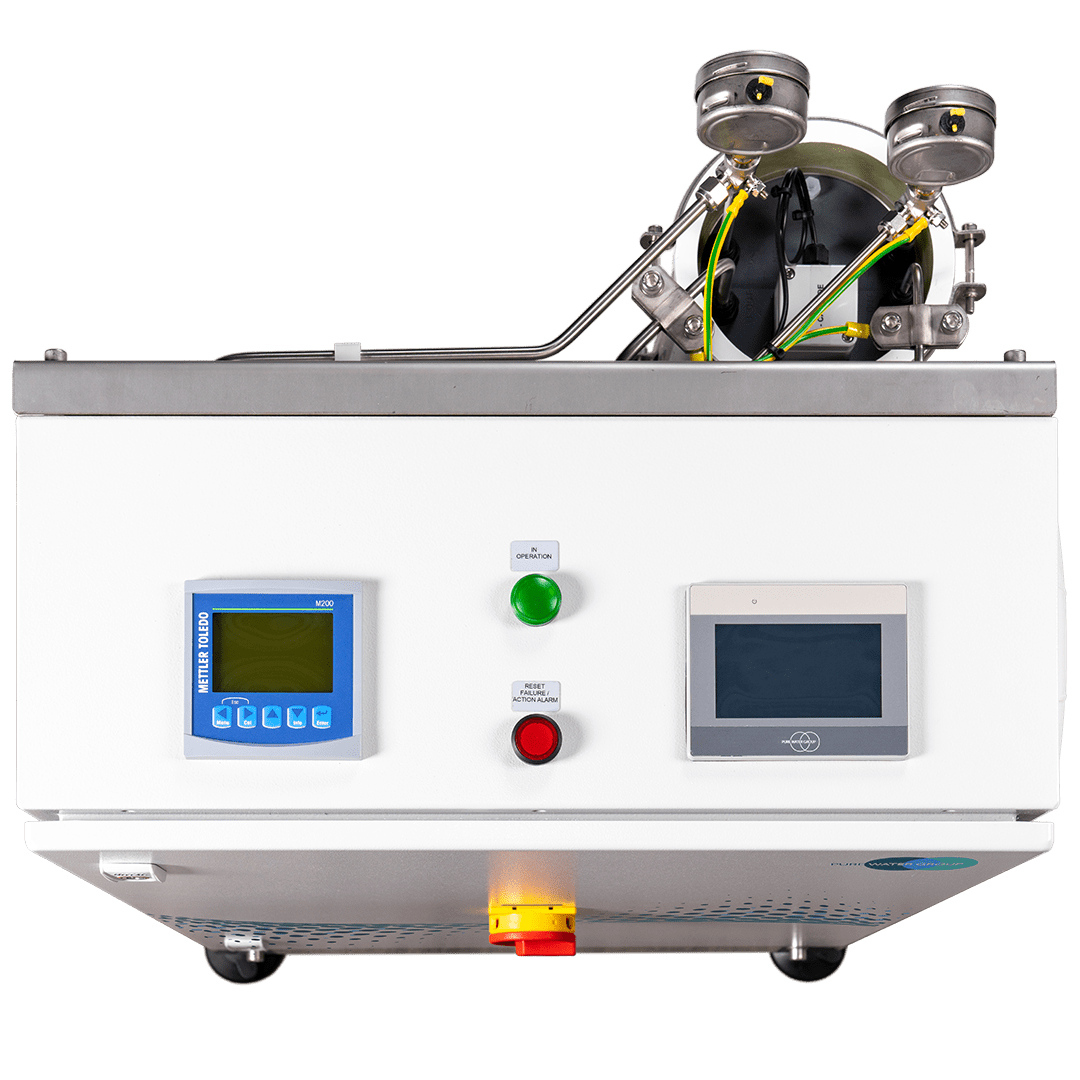

Control panel

The Control panel is located on top of the electrical cabinet of the CEDI system and consists of the Control Display and the Thornton conductivity instrument. The Control Display shows the actual voltage and amperage, time in operation and the set voltage and amperage. The Thornton conductivity instrument shows the actual conductivity and temperature of the CEDI product water

Unique system design

CEDI system highlights

The CEDI feed water inlet line, standard performed in PVC. The feed water inlet line splits into a feed water and into a concentrate water stream. A recovery control throttle valve is installed in the concentrate water stream, to regulate the concentrate flow and the total system recovery. The feed water stream (90-95%) will be purified in the product compartments of the CEDI module and the concentrate water stream (5-10%) will expel the concentrated ions out of the reject compartments of the CEDI module. The feed line connection is a 3-part union connection.

The CEDI feed water and concentrate water streams are monitored and safeguarded by flow- and pressure instruments. During operation the CEDI module is protected against low / no flow conditions by a flow switch on/off contact on both flow meters. In case of low / no flow the DC power to the CEDI module is switched off, if the flow is restored the DC power is switched on again. For safety reasons, the SST piping near the inlet of the CEDI module is grounded.

All components are mounted on a SST304 skid, supported by leveling feet for easy positioning. Wiring is routed safely and neatly through the mounting plate to the electrical control cabinet. The CEDI module contains push-in fittings for swift (dis)assembly of the CEDI feed water and concentrate water lines. The same feed water is fed to the CEDI module product and reject compartments.

The water outlets of the CEDI module, the product water stream (purified) and the reject water stream (concentrated) exits the CEDI module. The product water stream is monitored by a conductivity / temperature instrument. The product line connection is a 3-part union connection and the reject line connection is push-in fitting. Again, for safety reasons the SST piping near the outlet of the CEDI module is grounded.

The Control Panel is located on top of the electrical cabinet of the CEDI system and consists of the Control display and the Thornton conductivity instrument. The control display shows the actual voltage and amperage, time in operation and the set voltage and amperage. The Thornton conductivity instrument shows the actual conductivity and temperature of the CEDI product water.

The electrical cabinet is an IP54 rated, ventilated and lockable cabinet which accommodates the power supply, the microprocessor and all electrical controls and connections. The Main Power switch and CEDI system CE plate are located on the electrical cabinet.

Performance & Dimensions and weight

Experience, expertise and attention

We believe there are only a few companies in the world to rival what we do.

Thanks to our extensive experience in EDI solutions for power, pharmaceuticals, hemodialysis, petrochemicals and microelectronics applications, we developed essential insights into the technology and how it meets specific requirements ‘in the field’. This is reflected in the quality of training, service and validation we provide. So why not contact us? Our advice is free!