EDIpure Advanced

High ionic removal, Advanced and Plug-and-play.

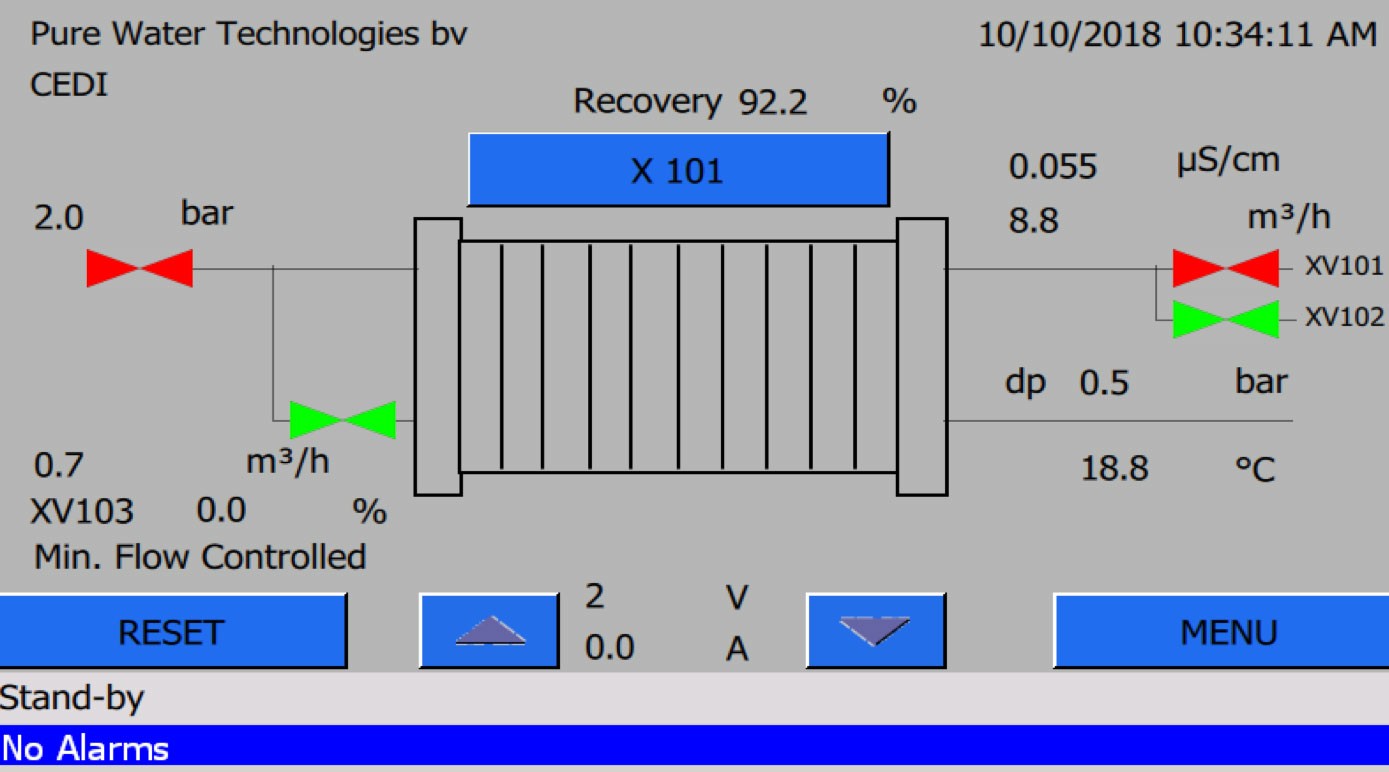

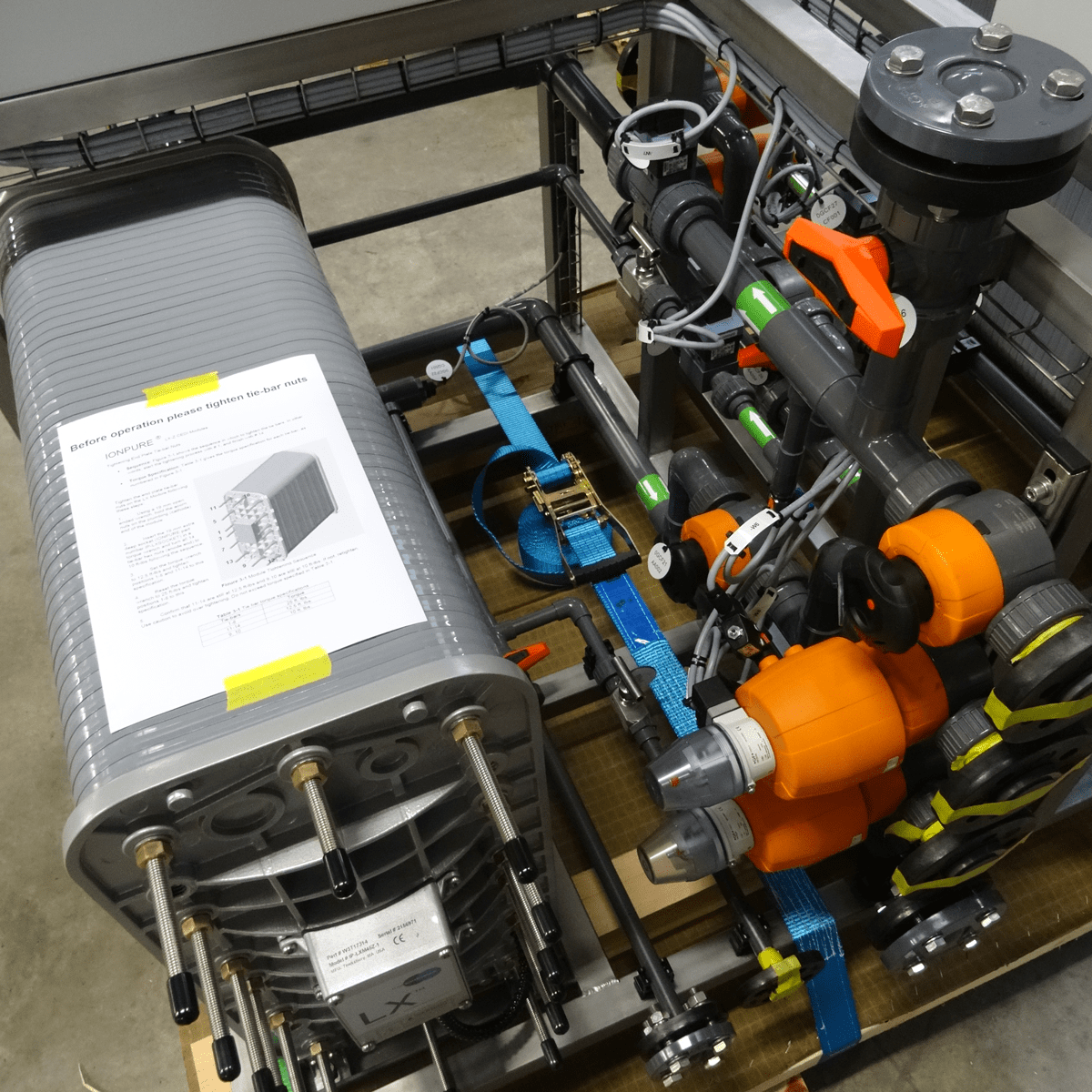

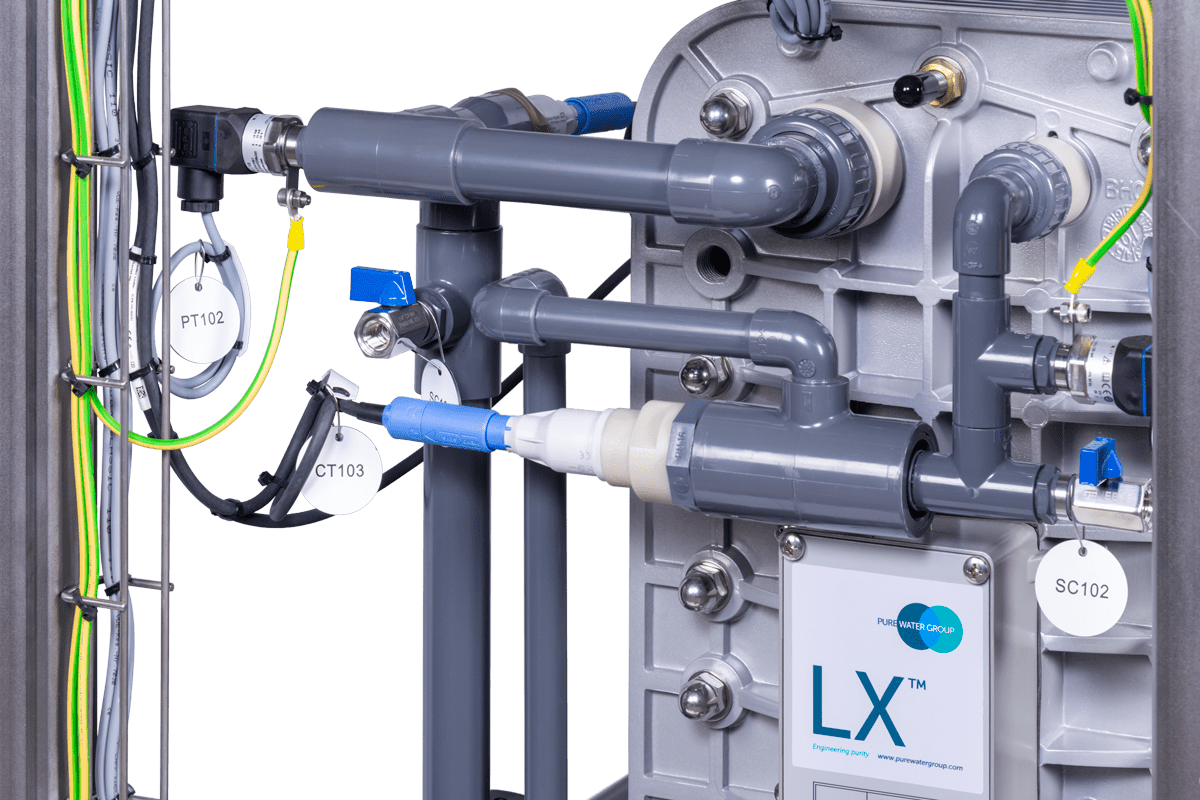

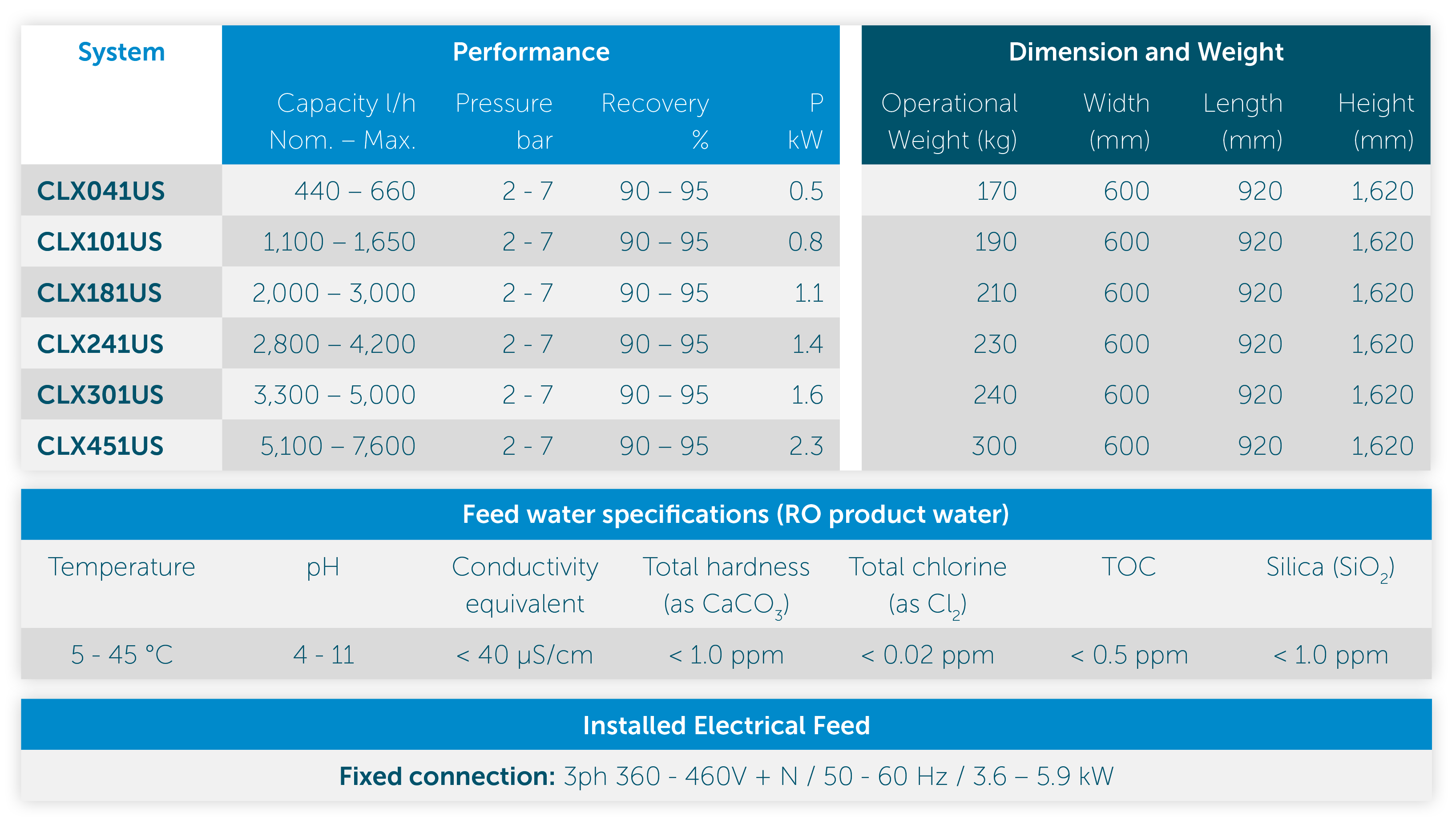

Our EDIpure Advanced Continuous Electrodeionization (CEDI) systems based on the LXM-X module are designed and manufactured to further purify reverse osmosis product water to ultra pure or high purity water (0.055 – 0.5 µS/cm). These pre-engineered and ready-to-run CEDI systems are fully factory acceptance tested to significantly reduce installation and start-up costs and are available in a range from 0.22 to 7.67 m3/h. The outstanding design and use of Ionpure’s® patented continuous electrodeionization technology ensures high reliability, minimizes maintenance and eliminates use of regeneration chemicals.

Technology

How it works.

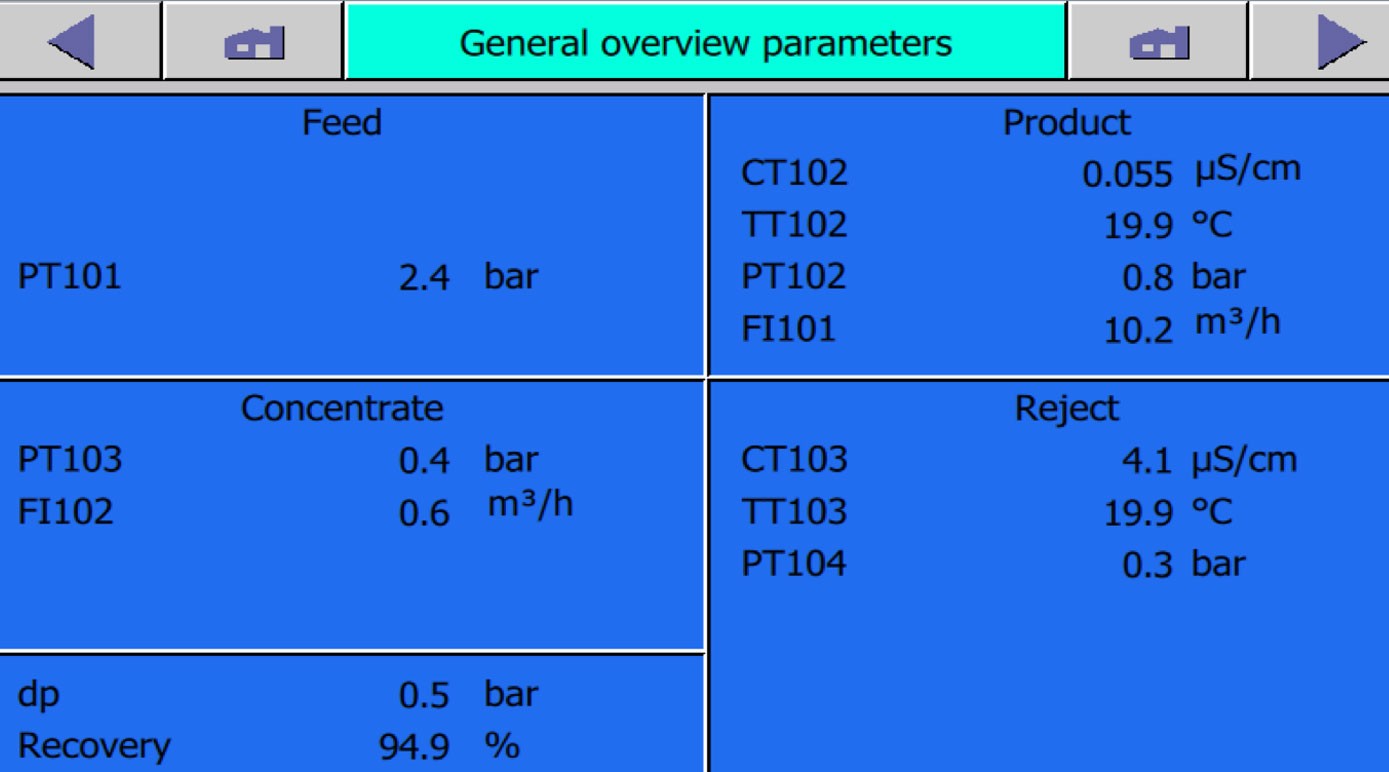

The water passing through the product compartments is deionized to pure water, while the rest of the water is flowing into the reject compartments. This water takes away concentrated salts and small amounts of gases formed on the electrode surfaces. The reject water exiting the CEDI system is typically re-used and mixed with the RO feed water in a vented break tank.

Control & Construction

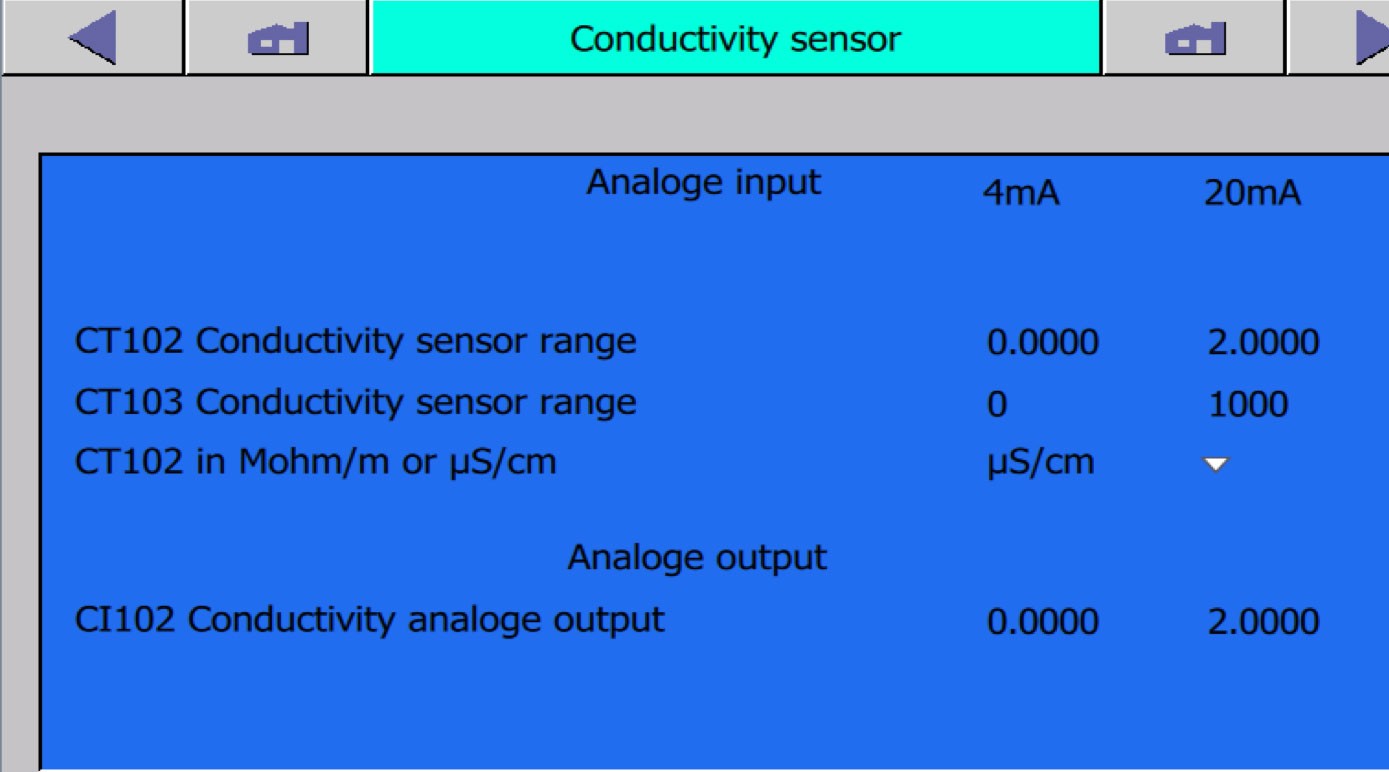

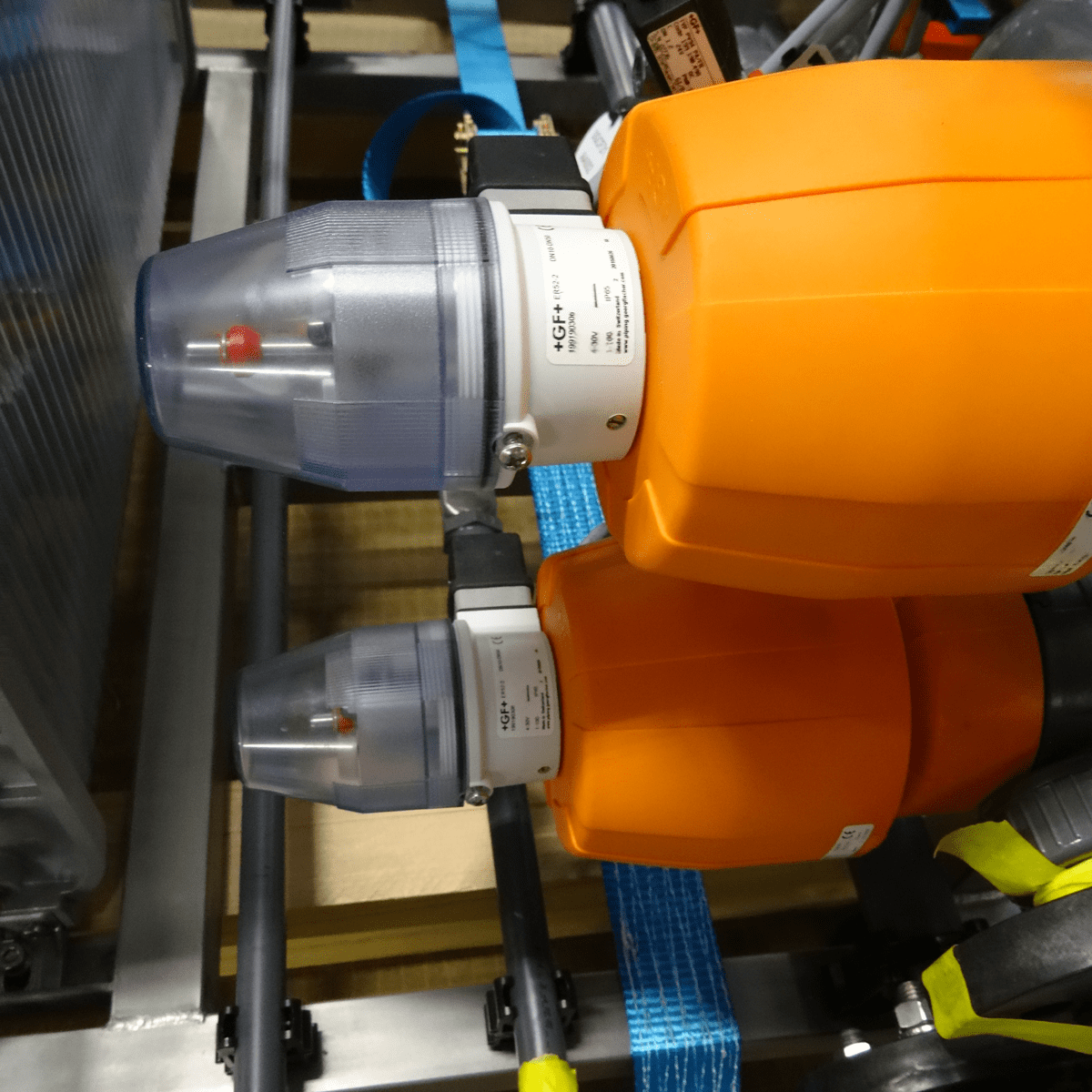

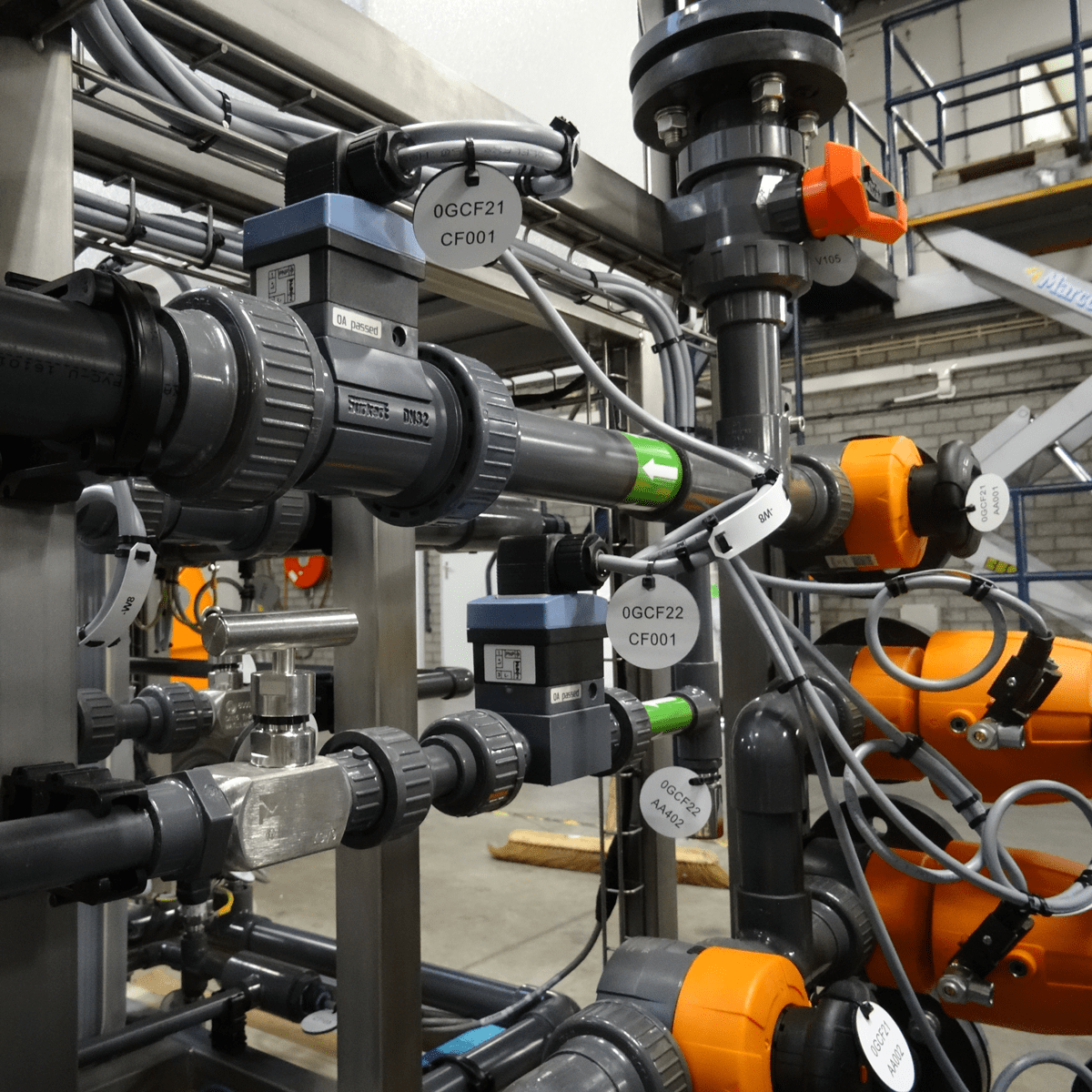

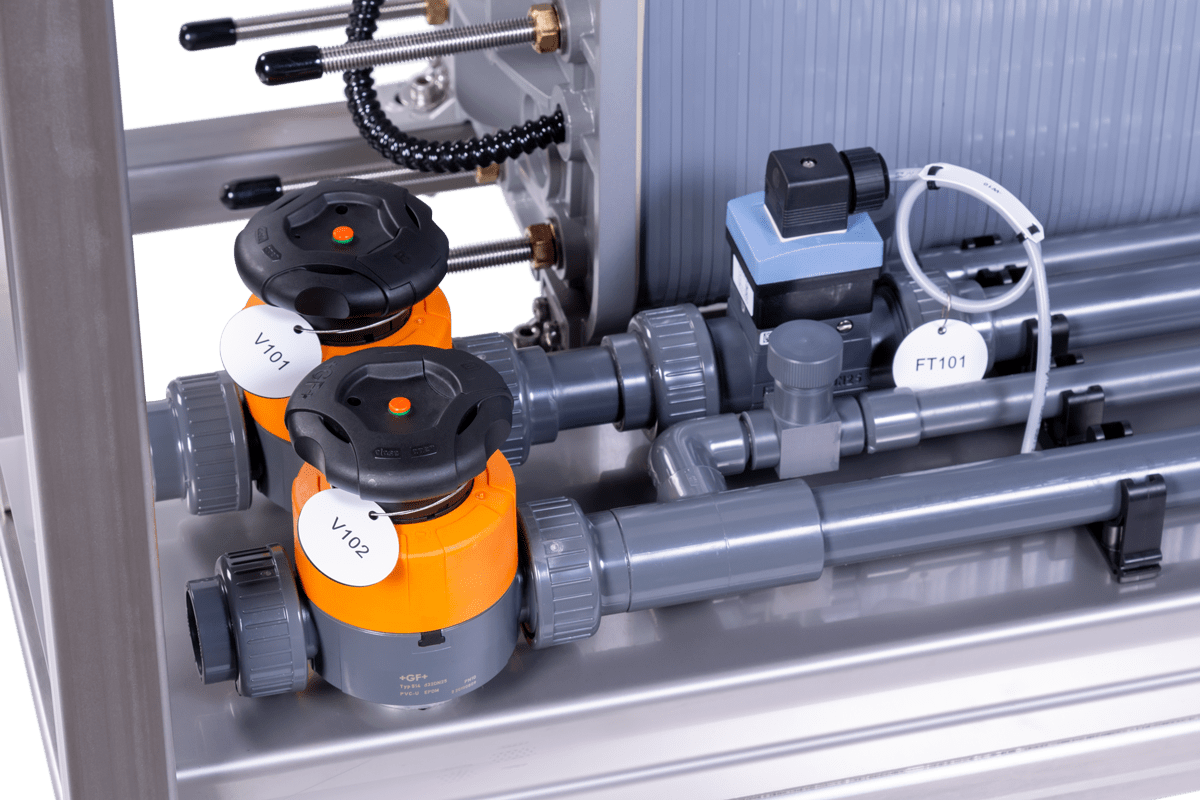

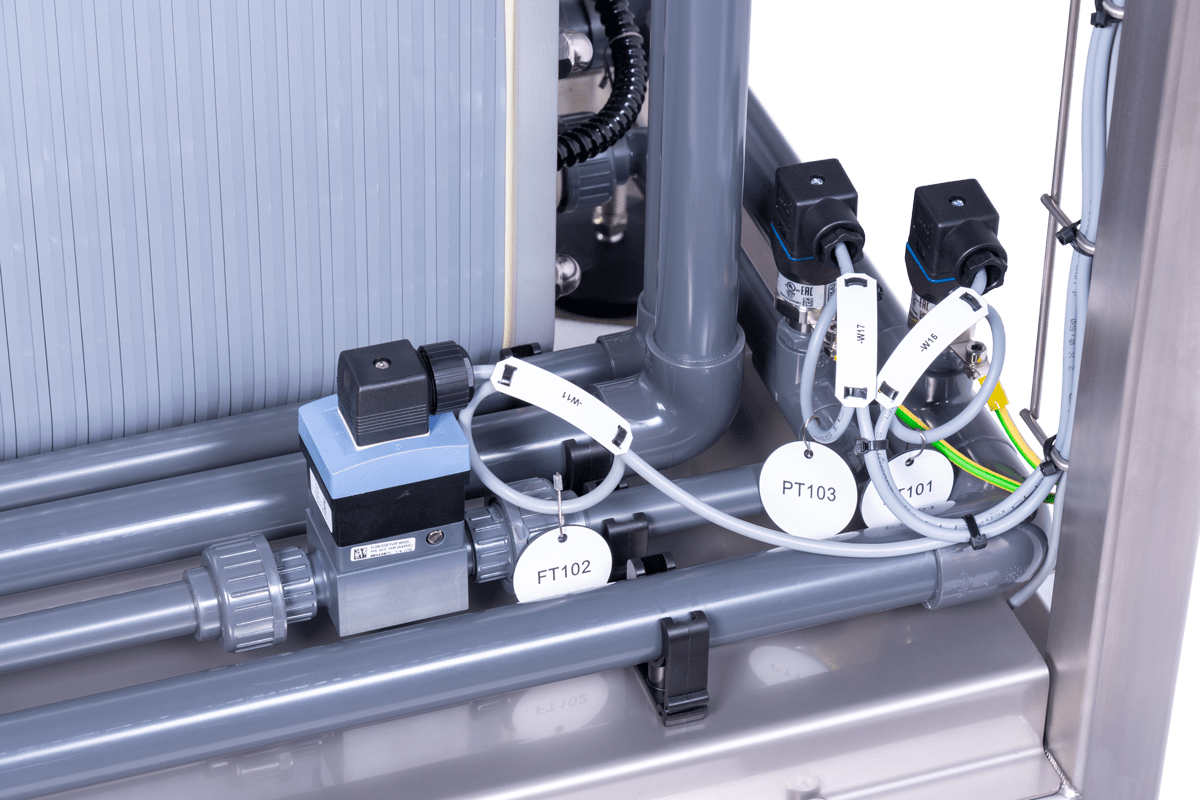

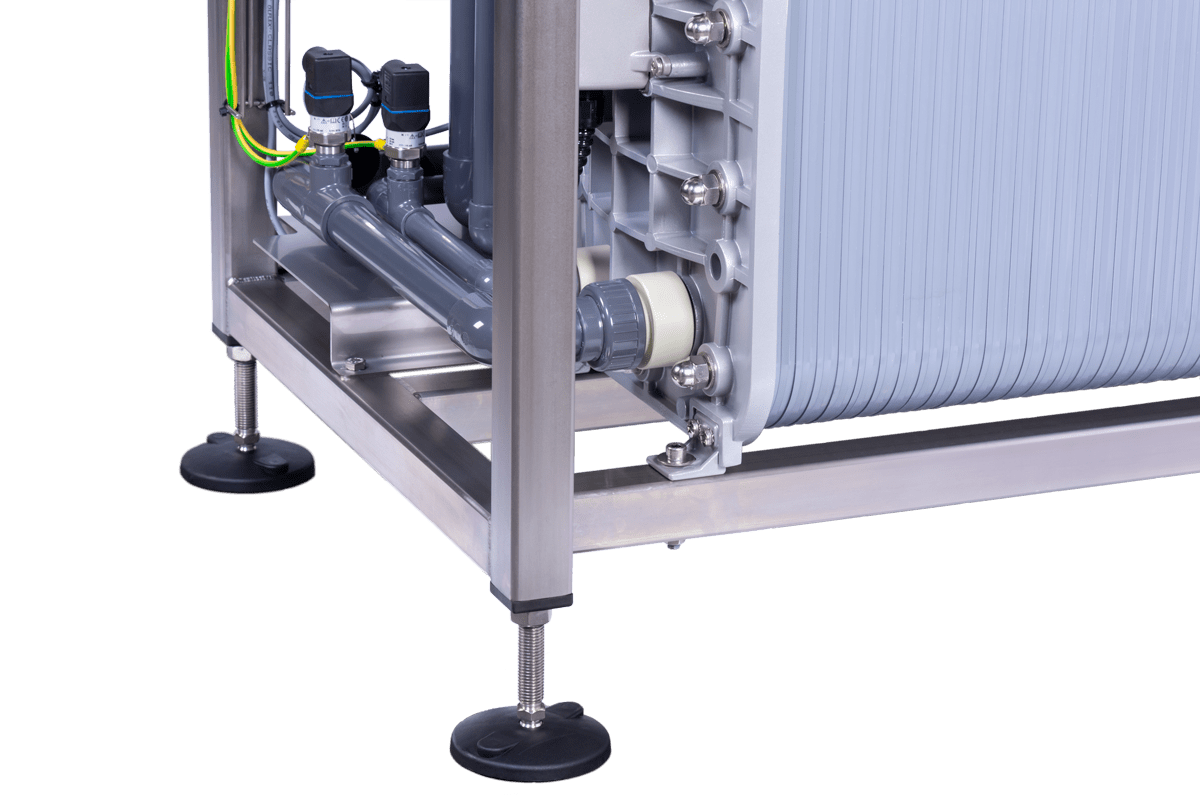

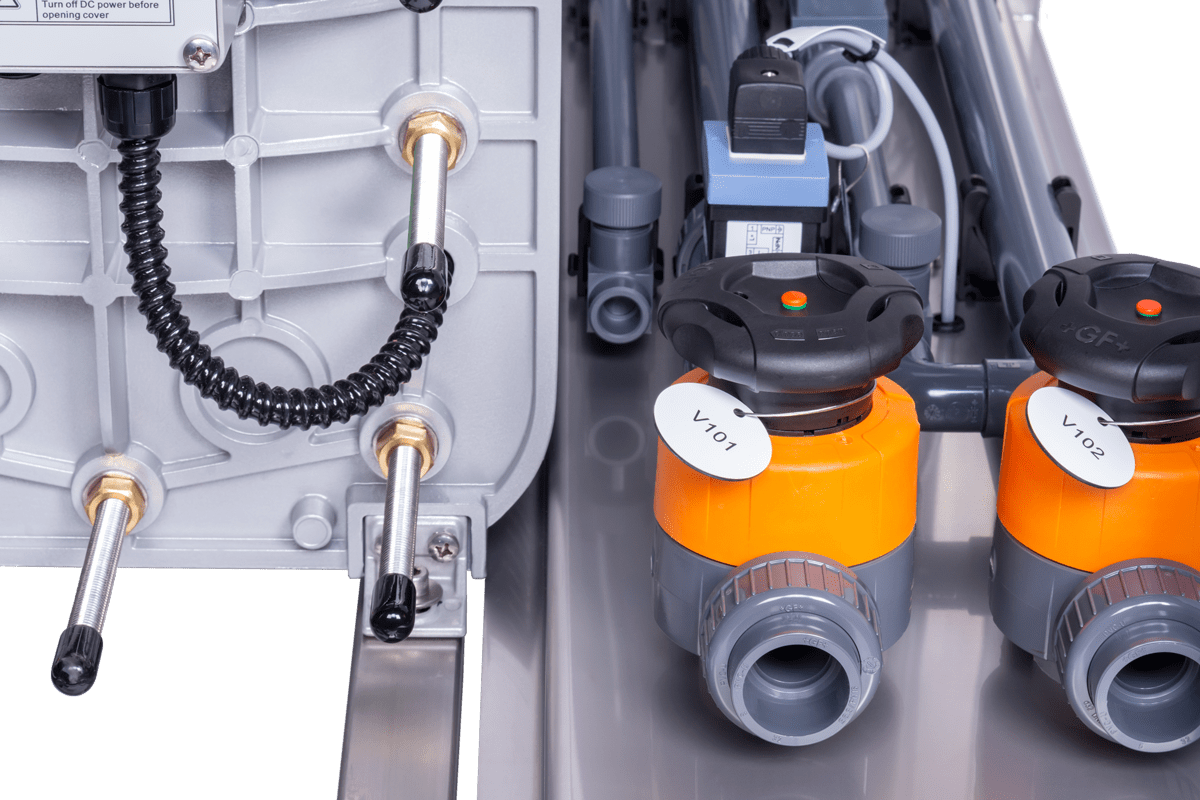

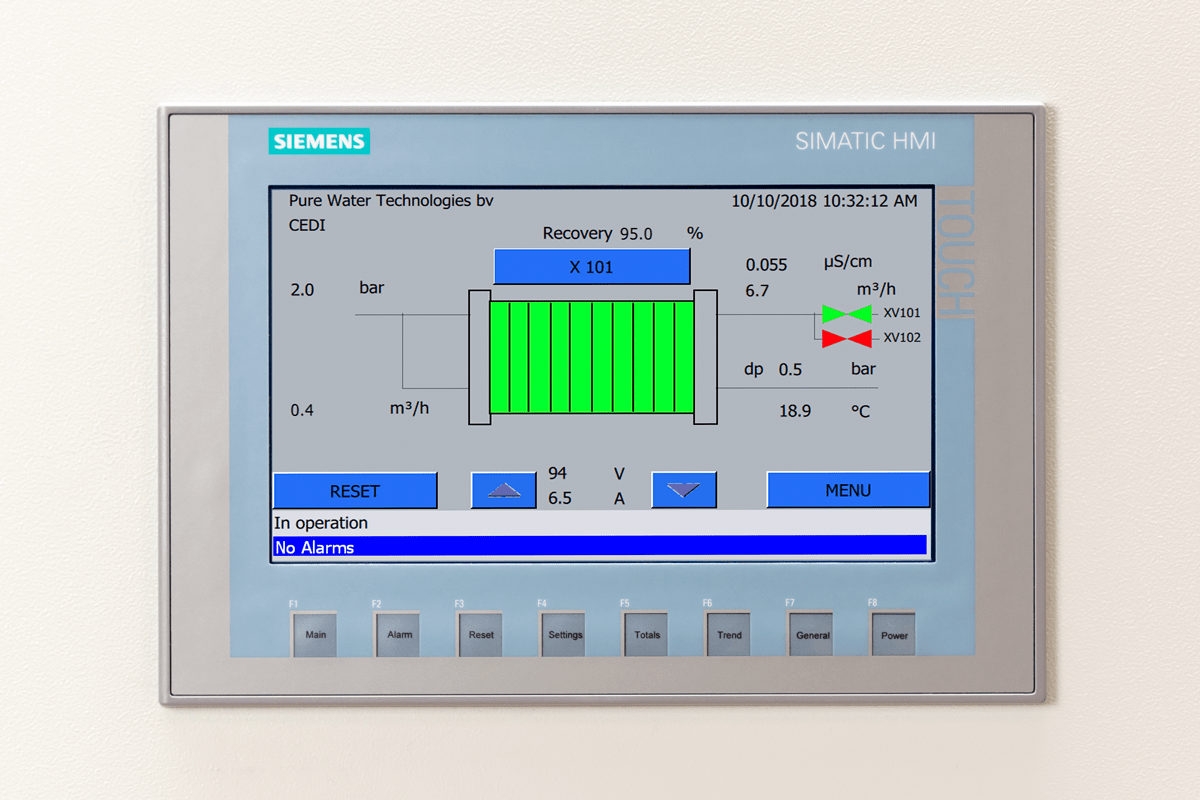

EDIpure Advanced systems are skid mounted and include a sophisticated control system based on standard PLC / HMI interface and all necessary instrumentation for a reliable and continuous operation. The control system allows easy integration of feature options and auxiliary communication via Ethernet, Modbus or Profibus. Piping is available in PVC, PP or Stainless Steel. These CEDI systems are specifically designed for high ionic removal including weakly charged ions like silica, boron and CO2 (up to 18 MOhm.cm).

CEDI technology features:

- Continuous process, constant product water quality

- Low operating costs, electricity only

- Environmentally friendly, no regeneration chemicals

- High system recovery up to 95%

- Typically the reject water is recirculated upstream RO

- 1000’s systems installed worldwide

Unique system design

CEDI system highlights

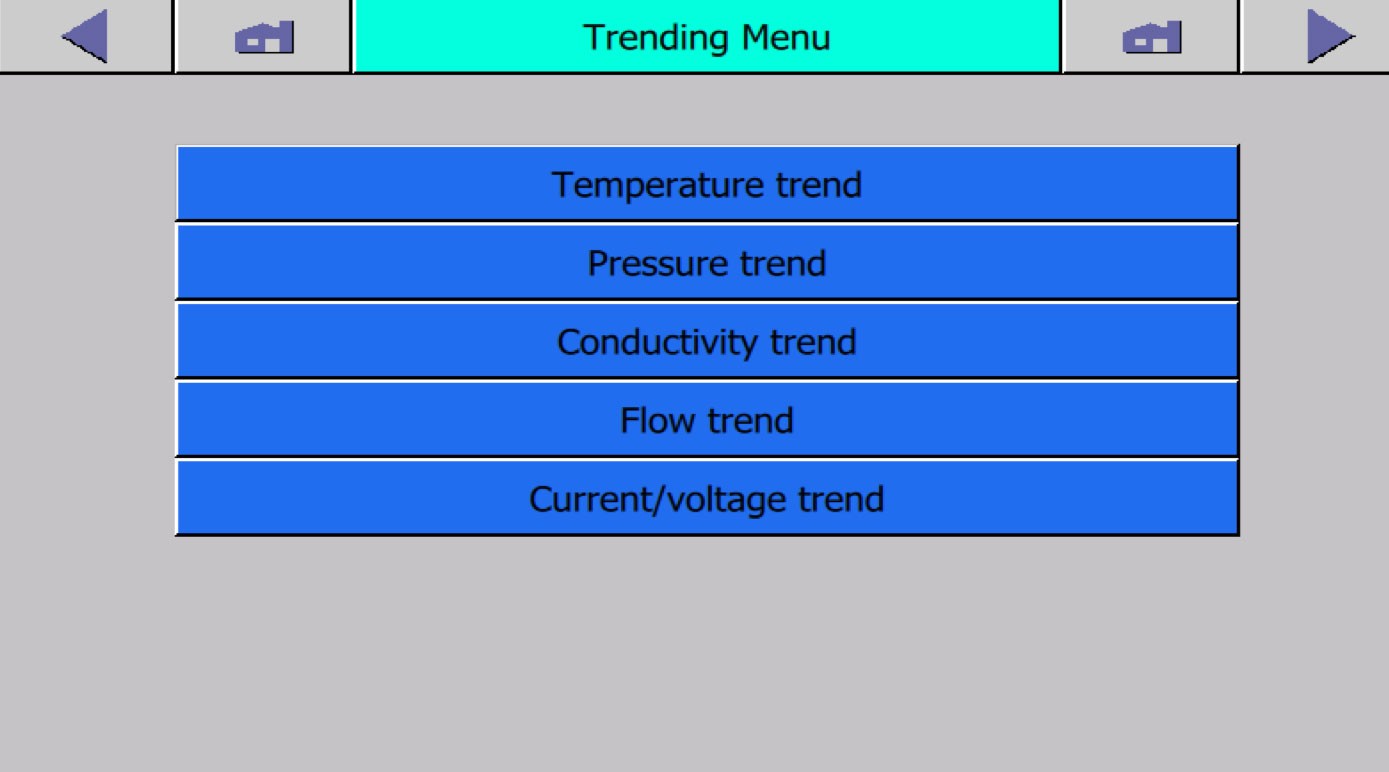

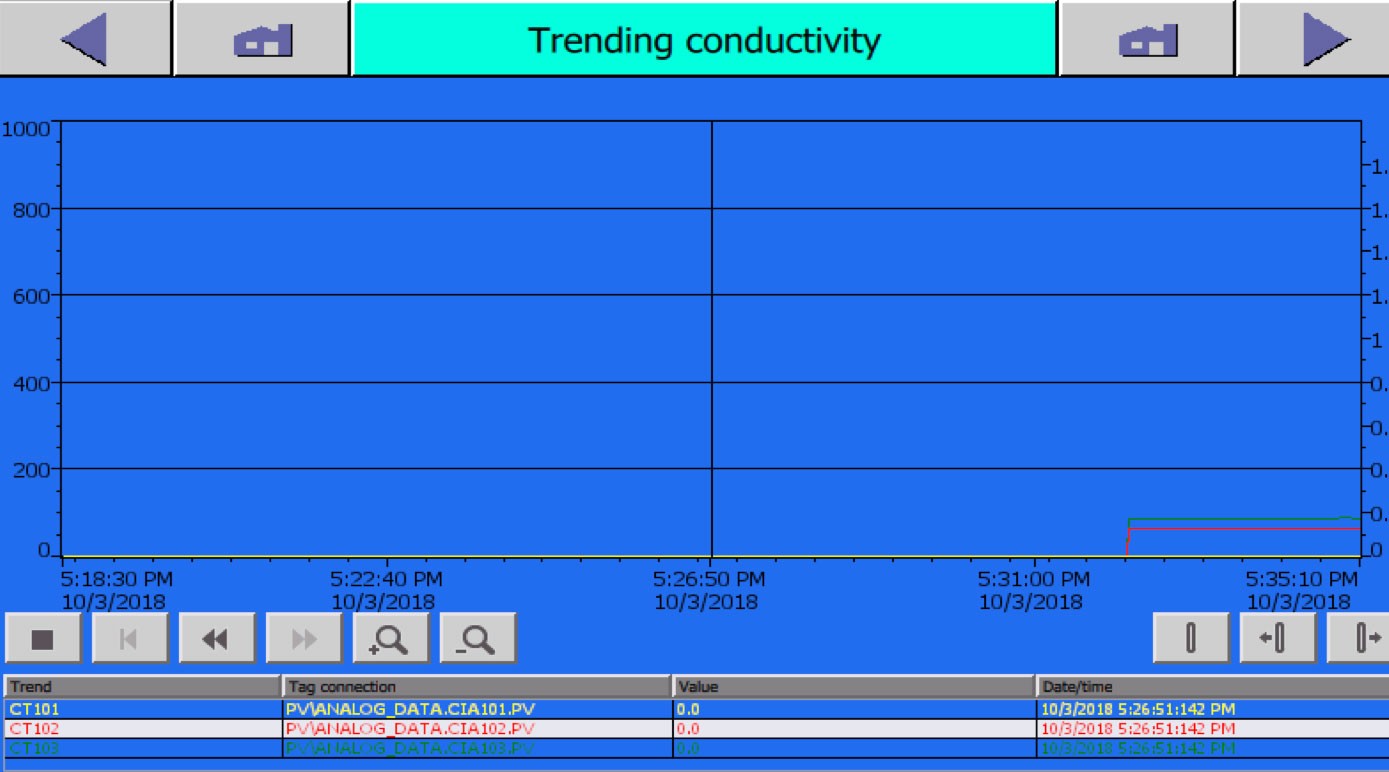

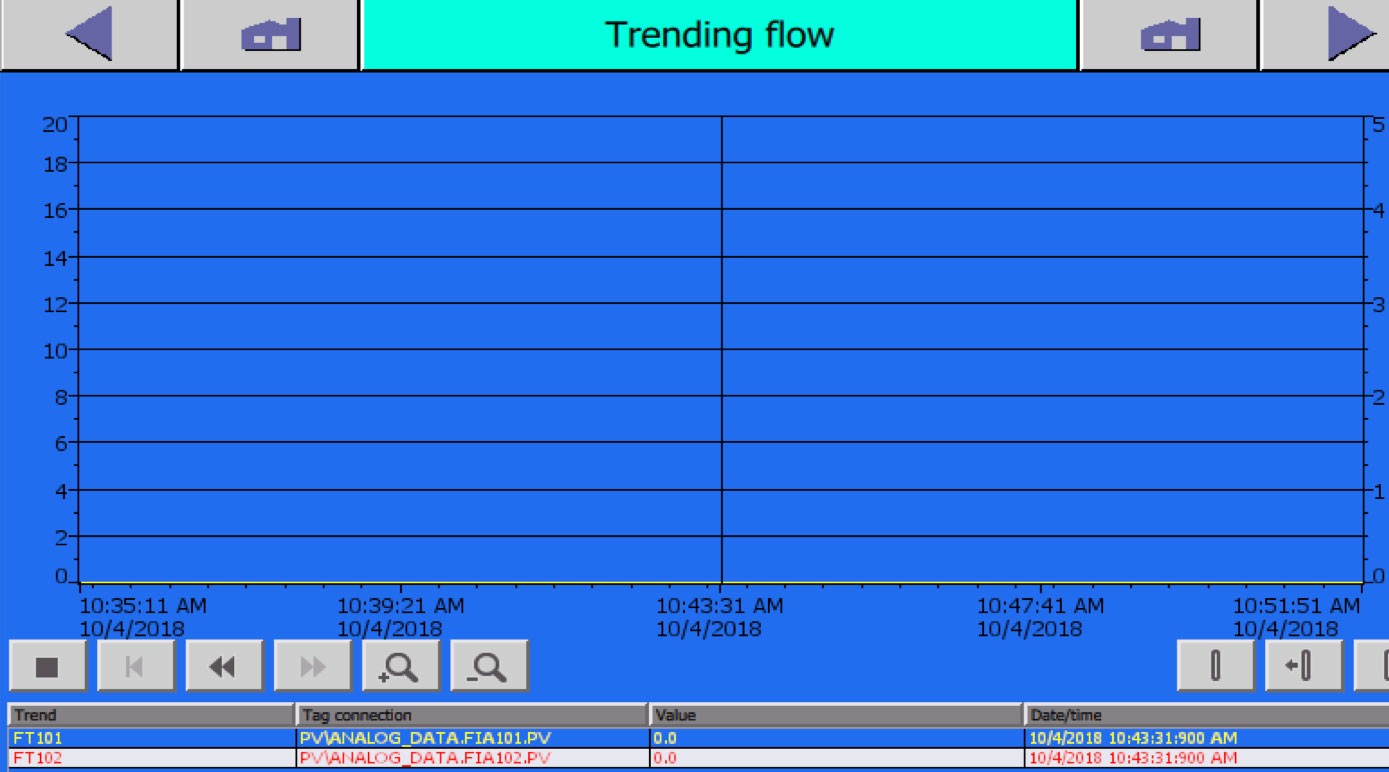

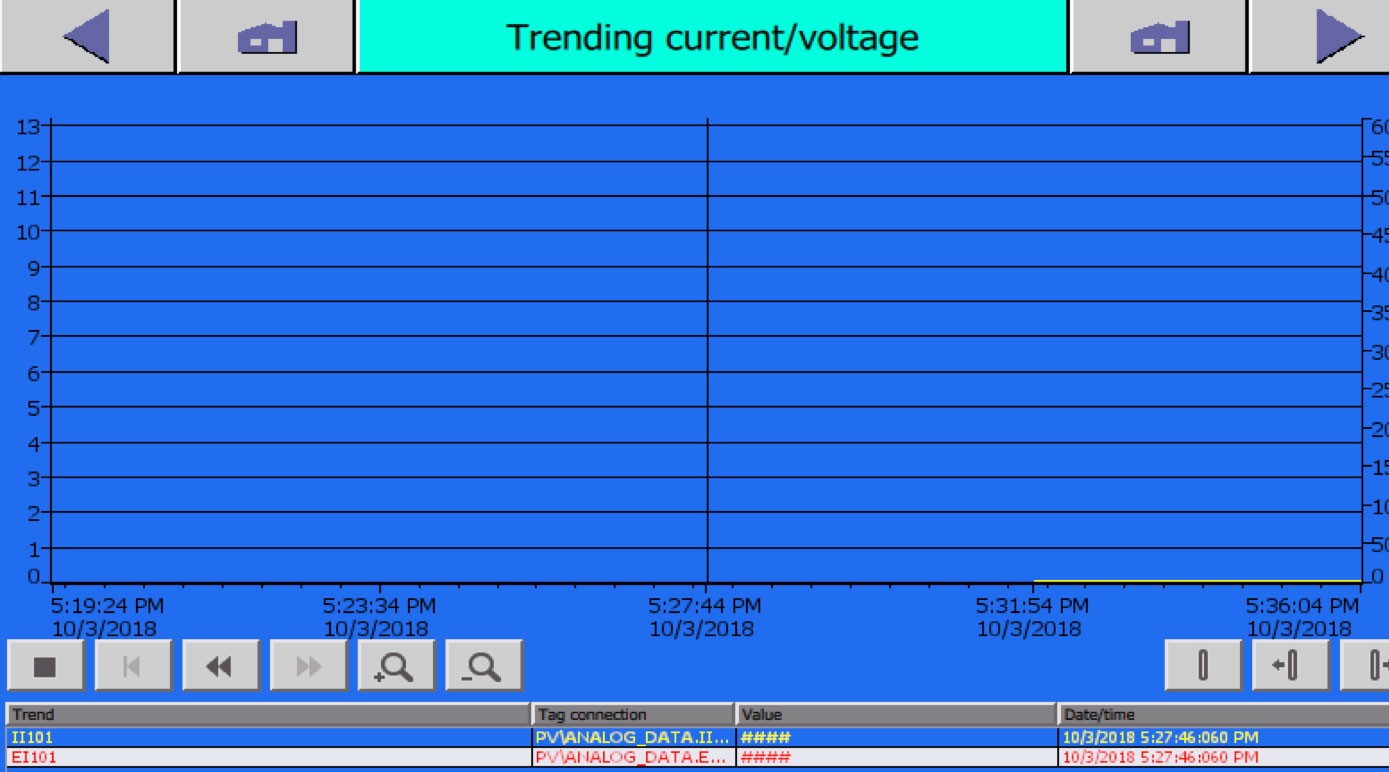

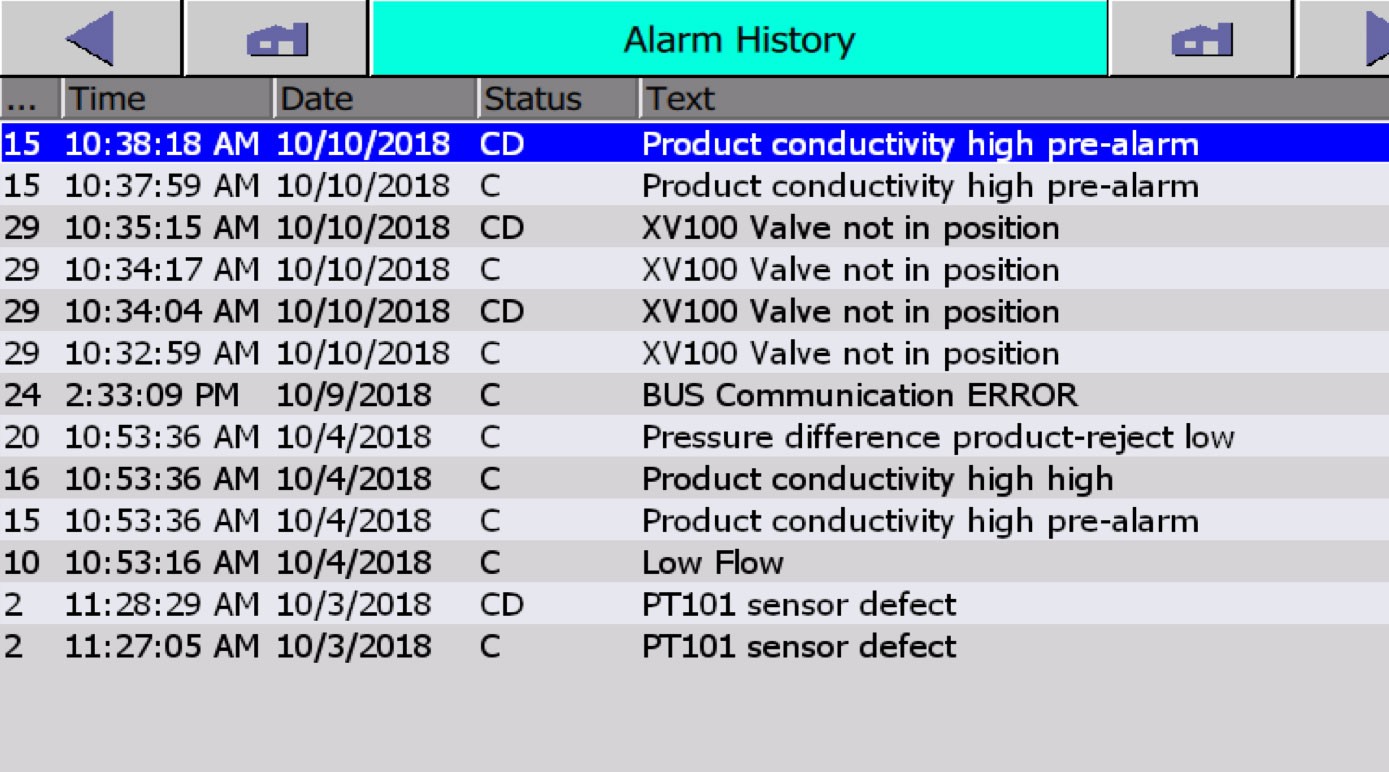

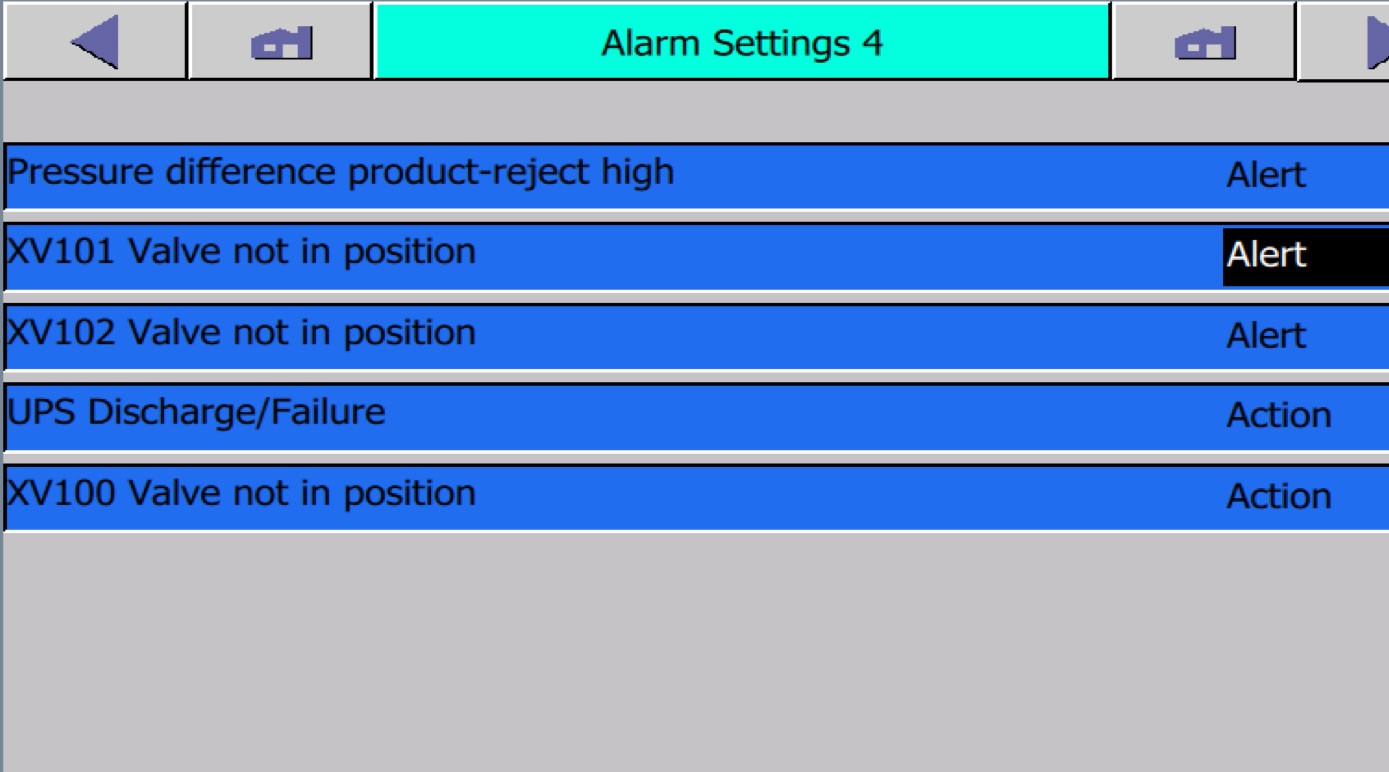

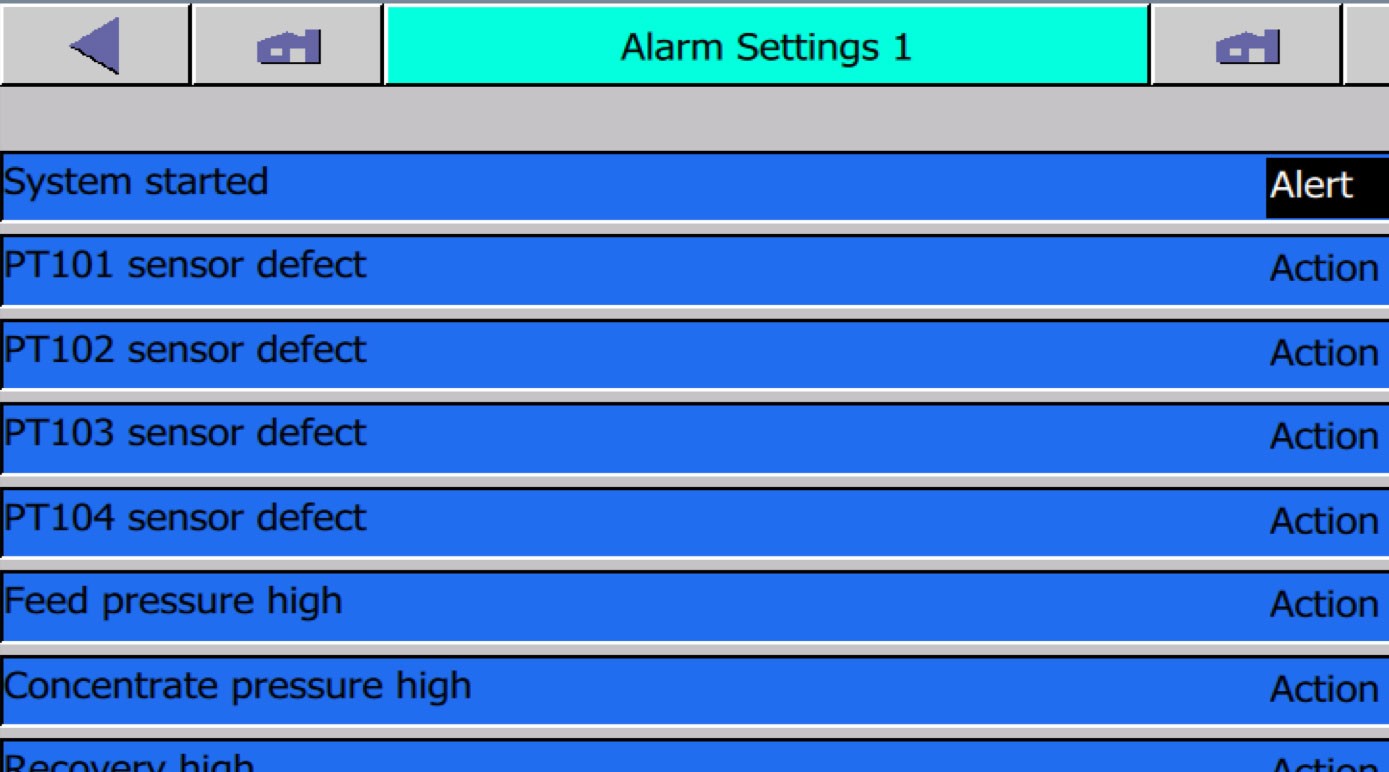

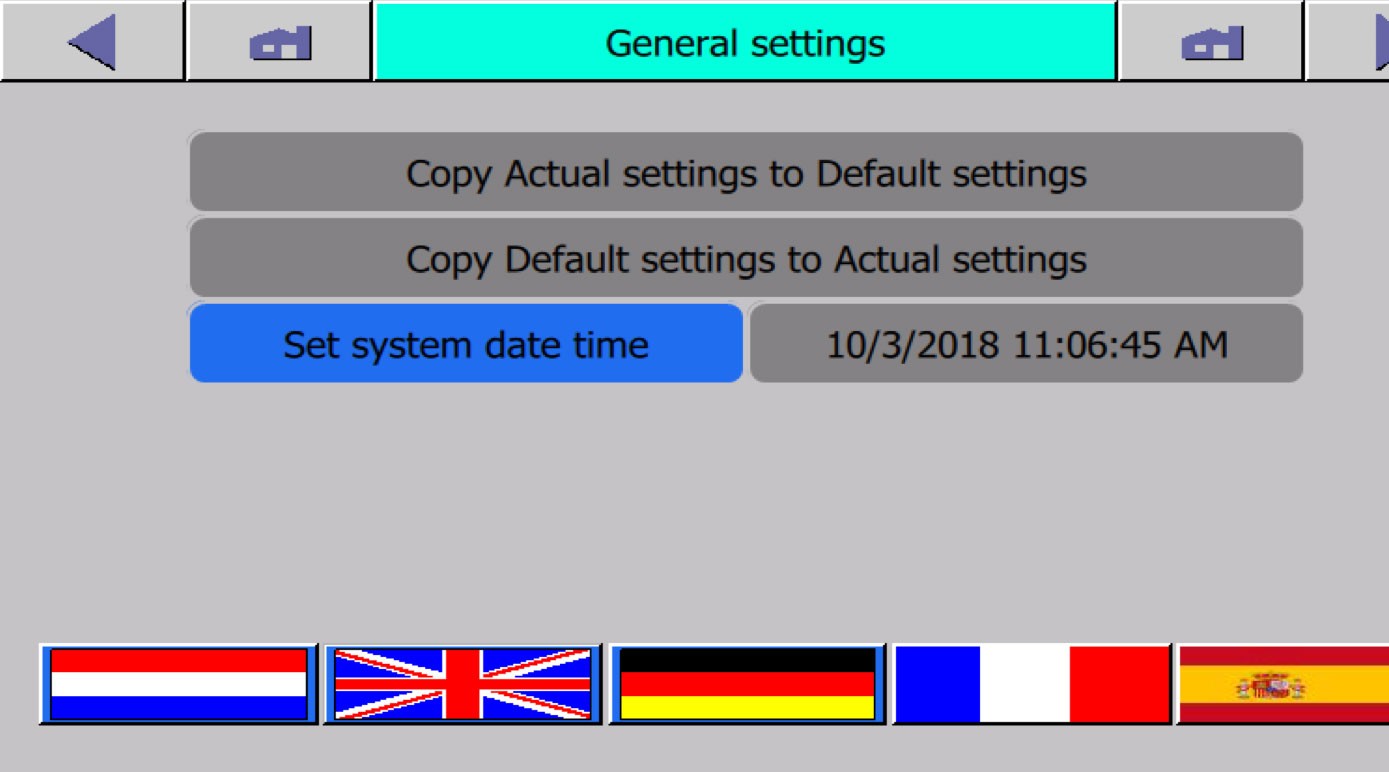

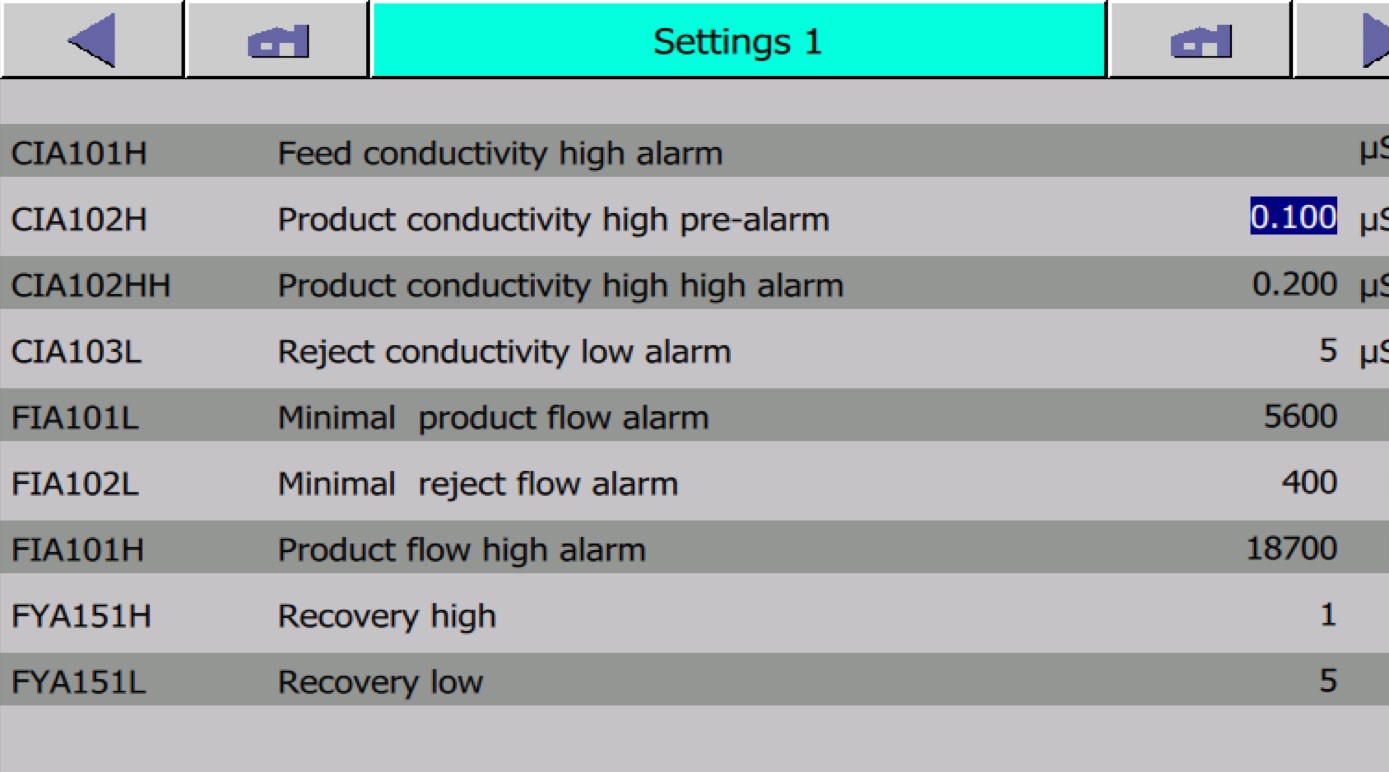

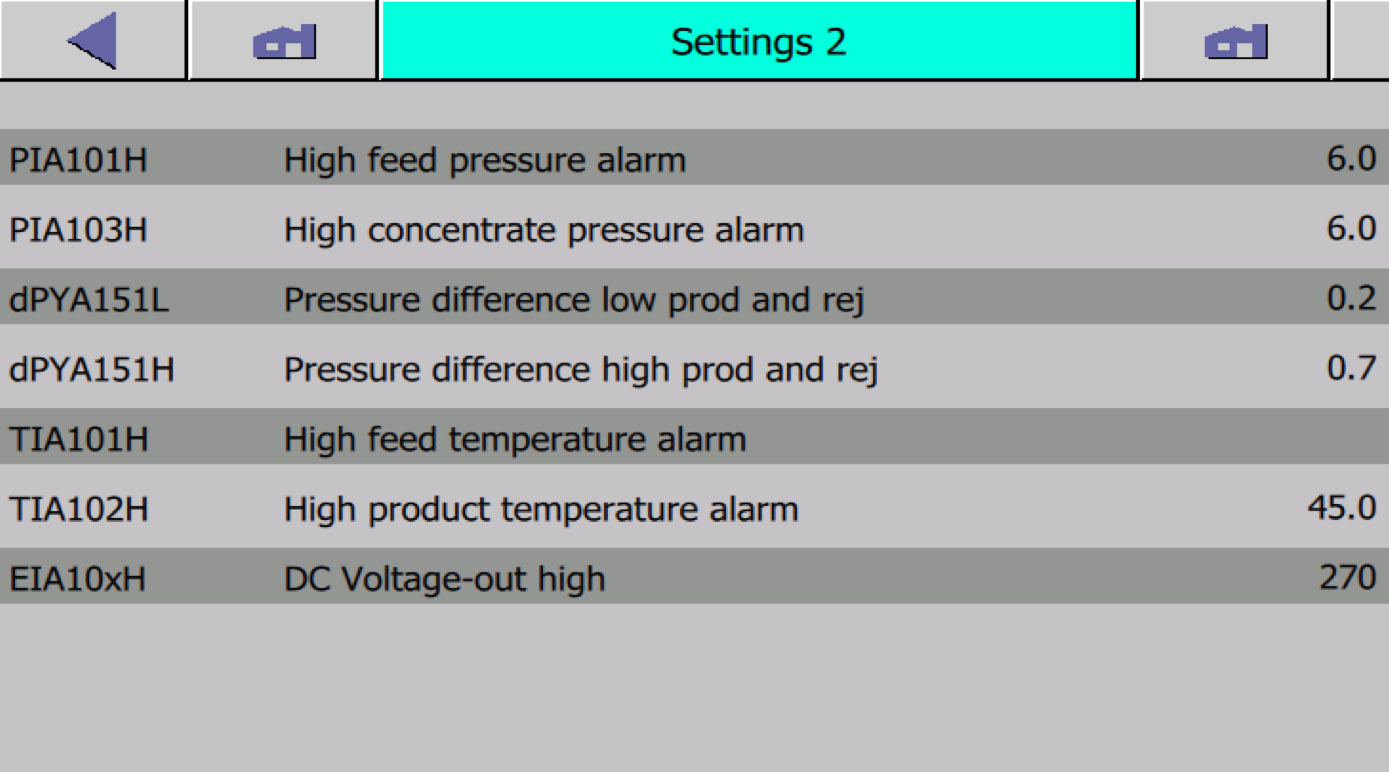

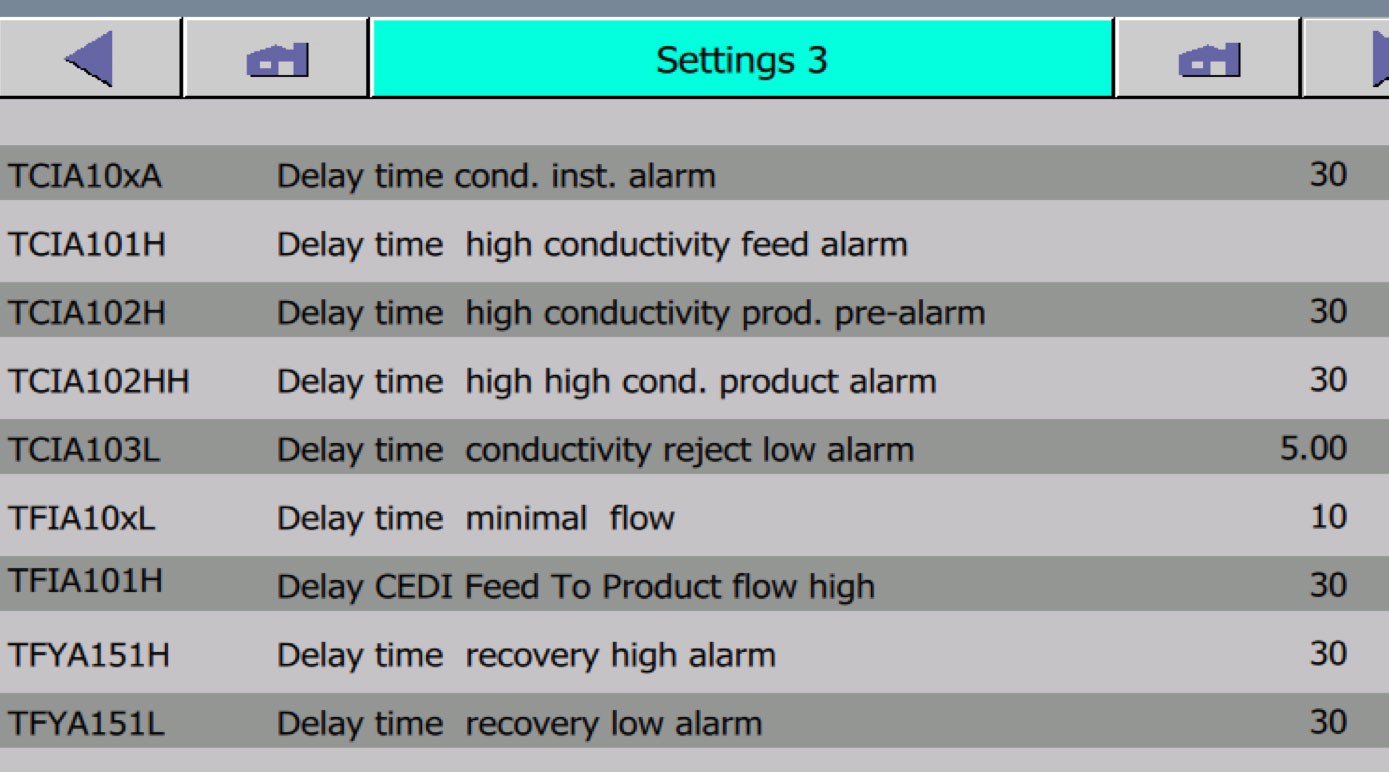

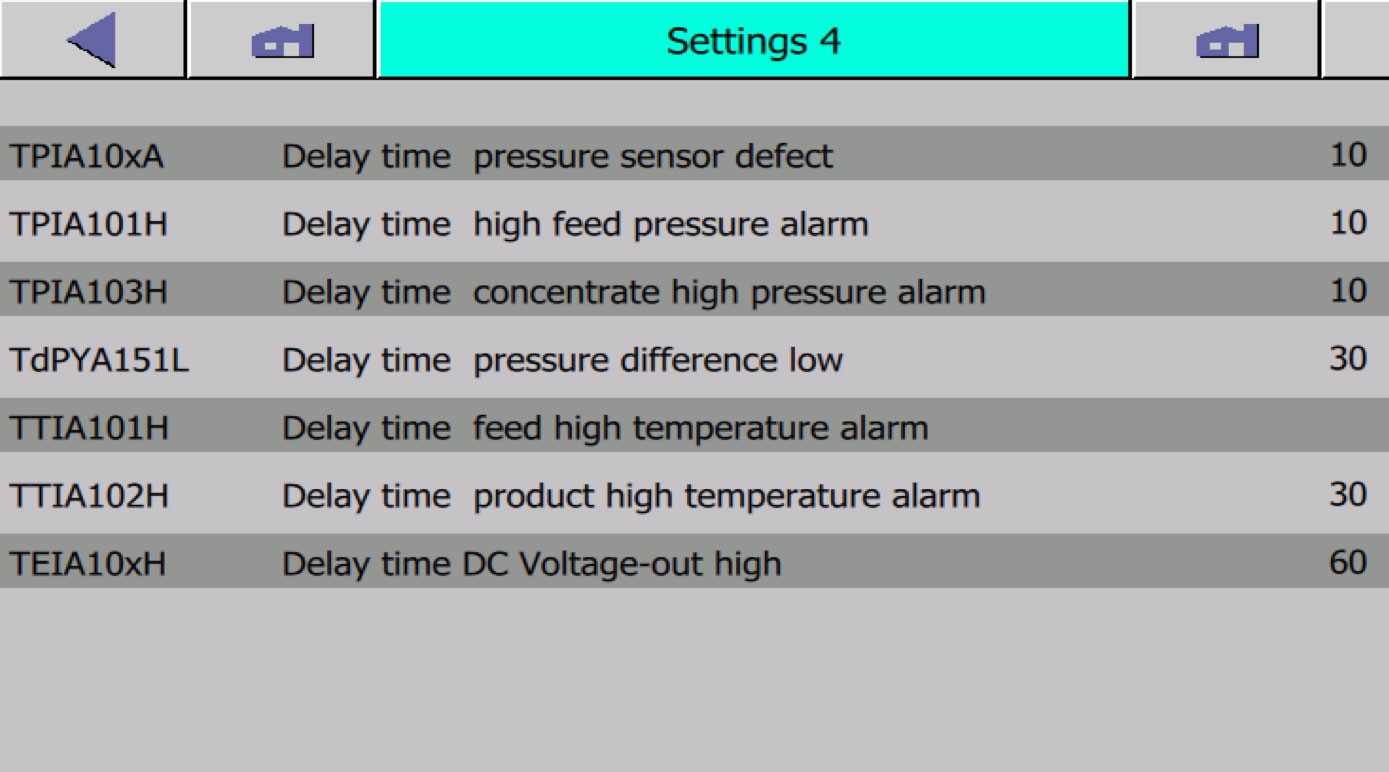

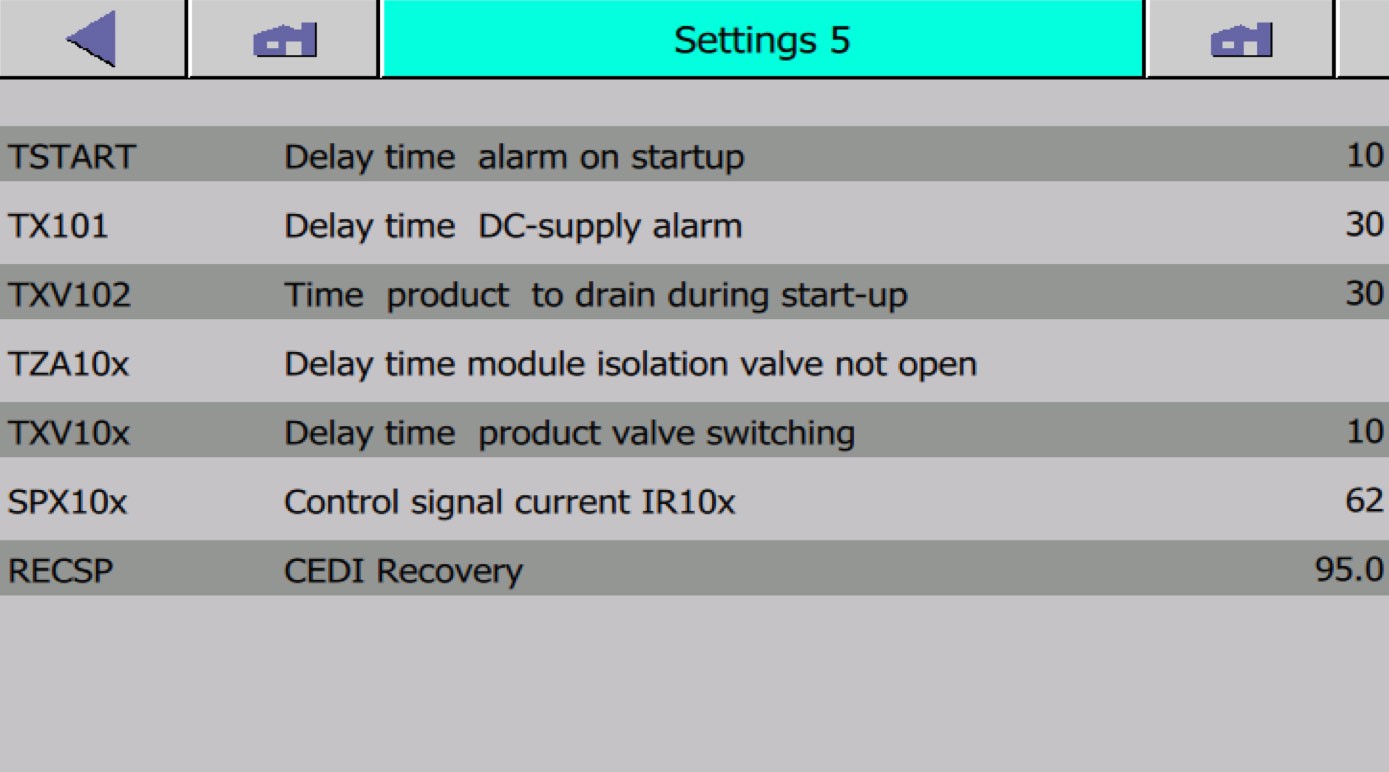

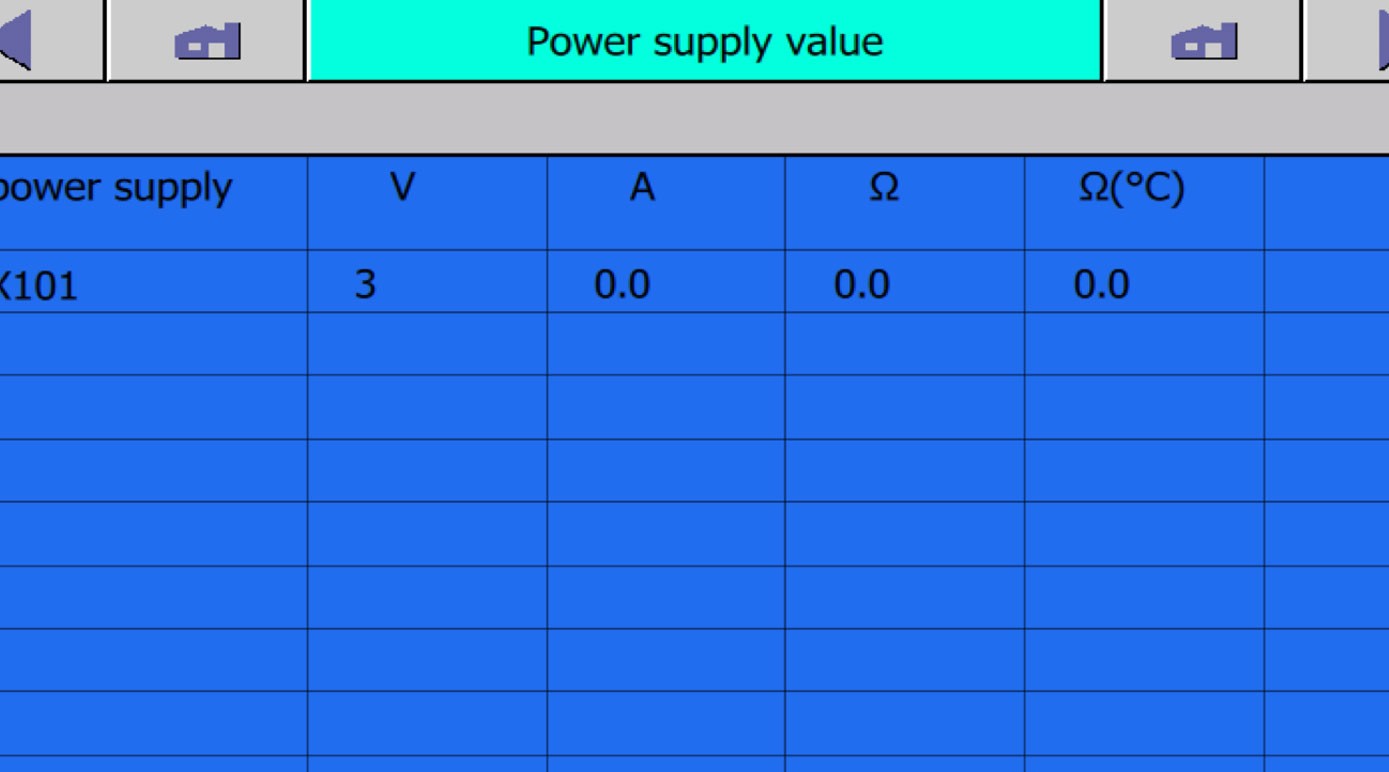

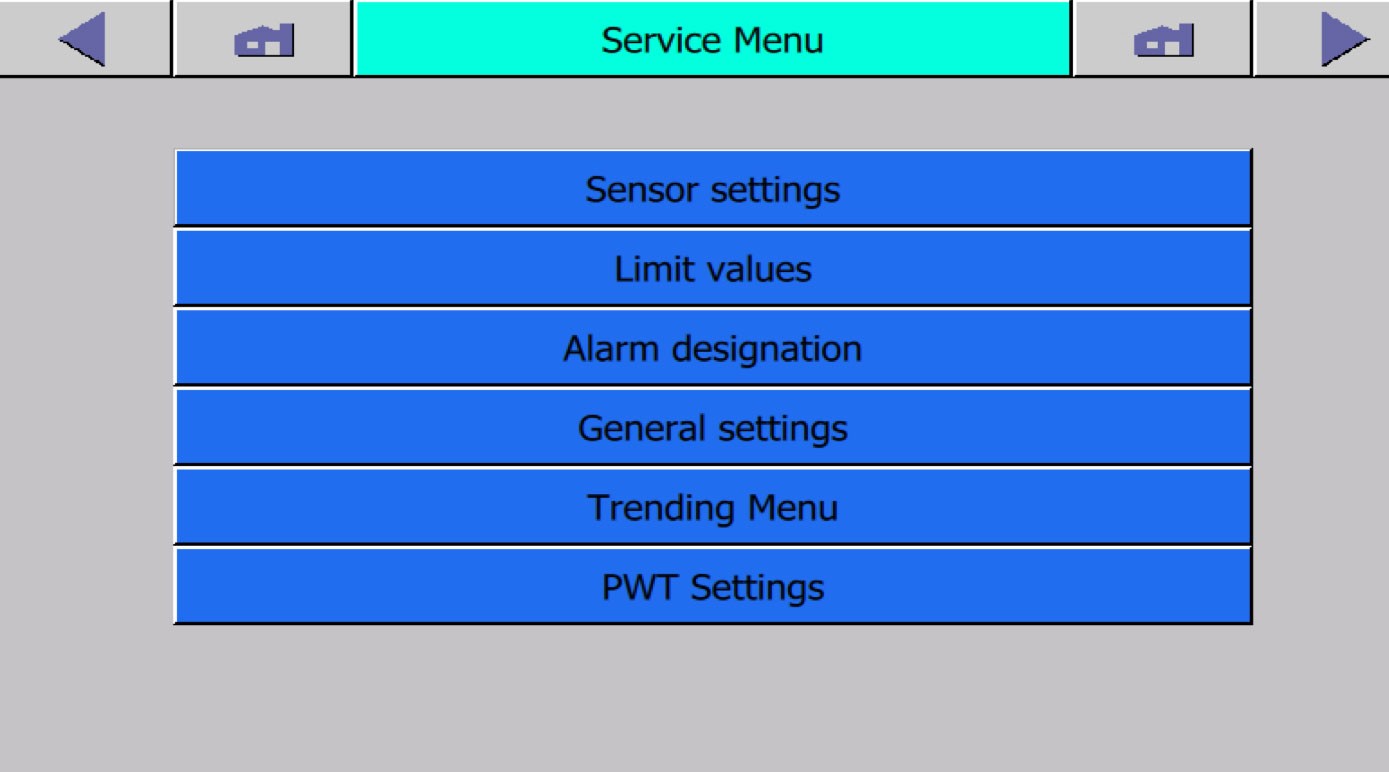

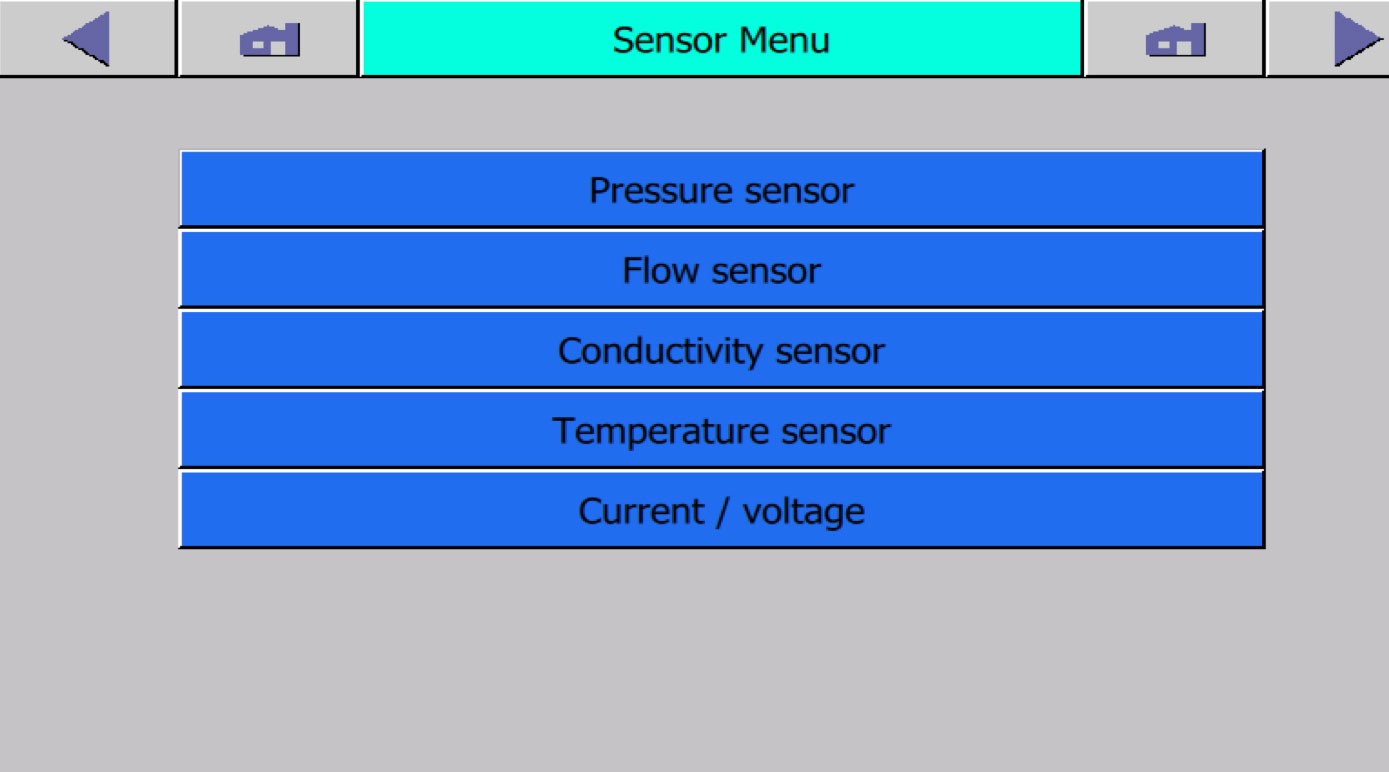

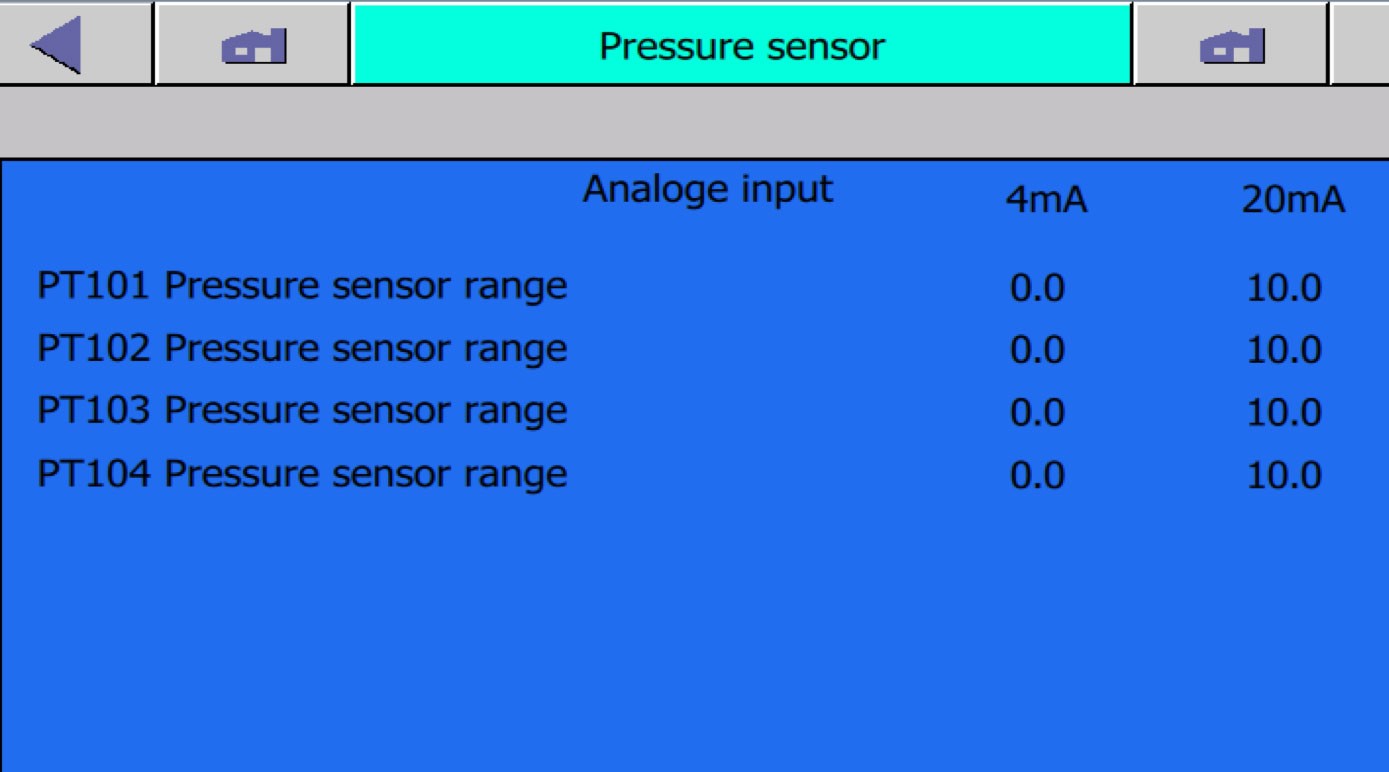

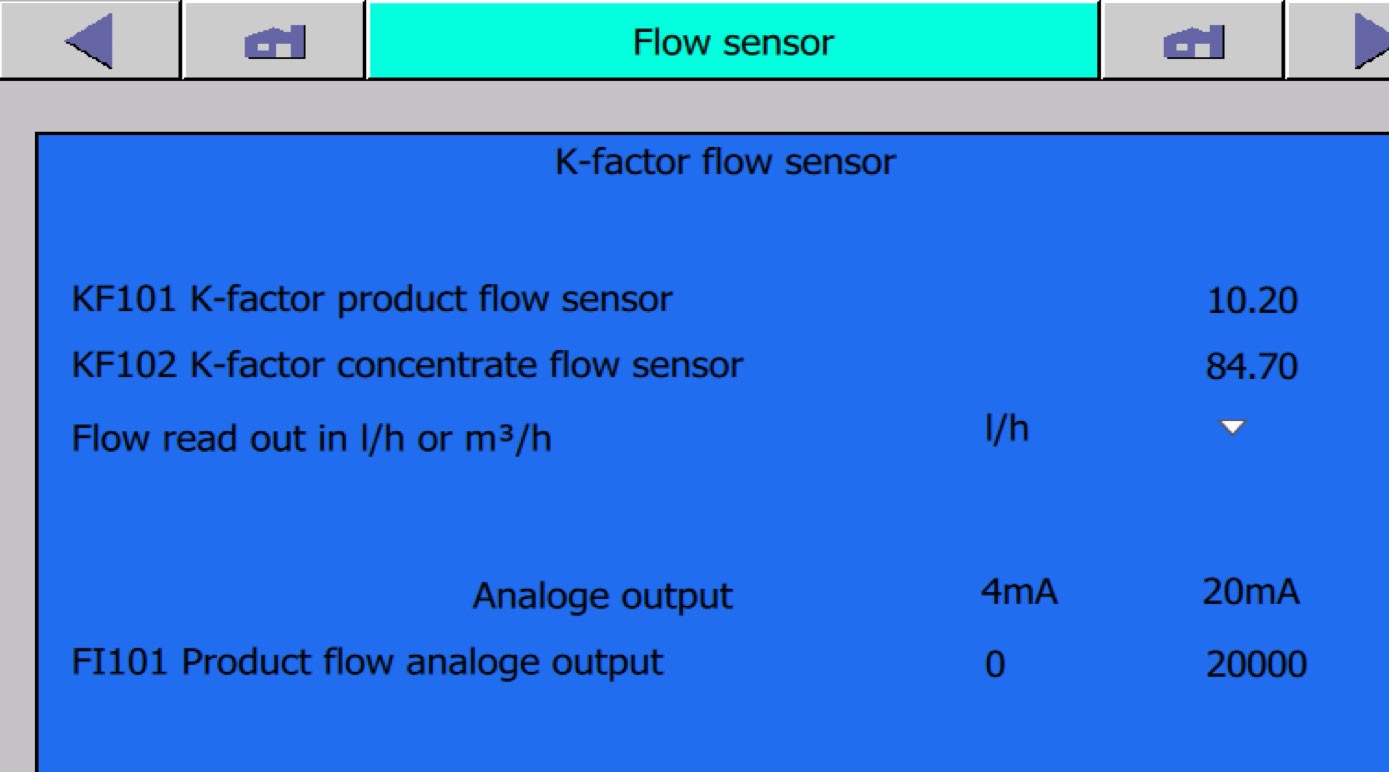

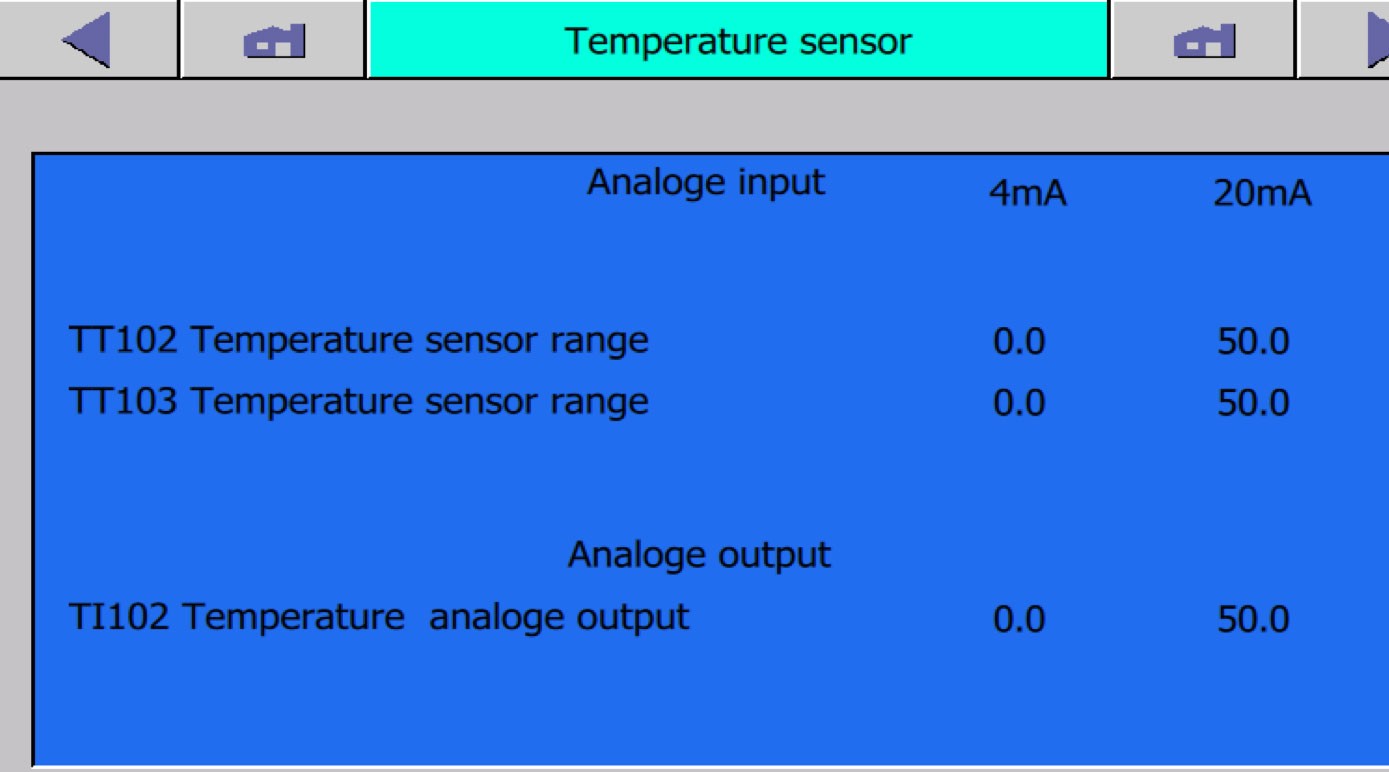

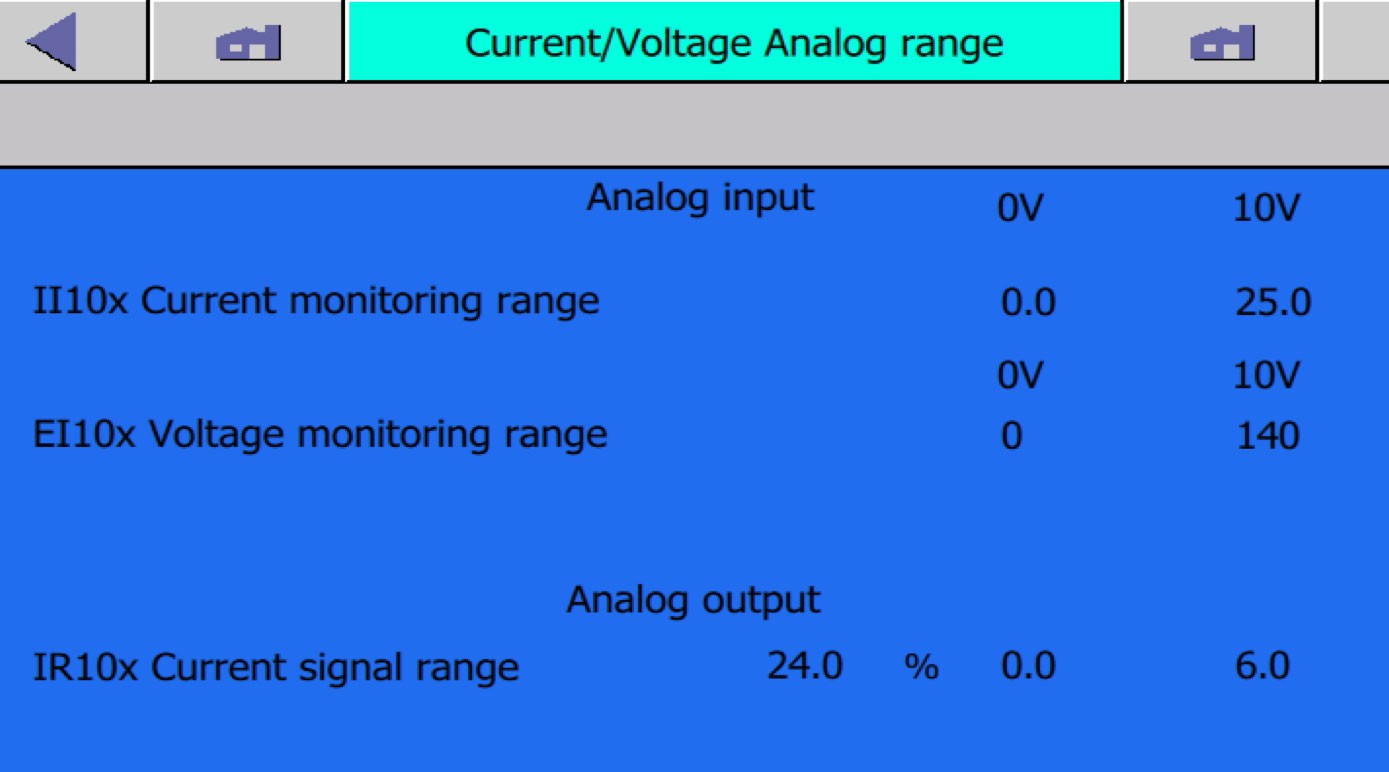

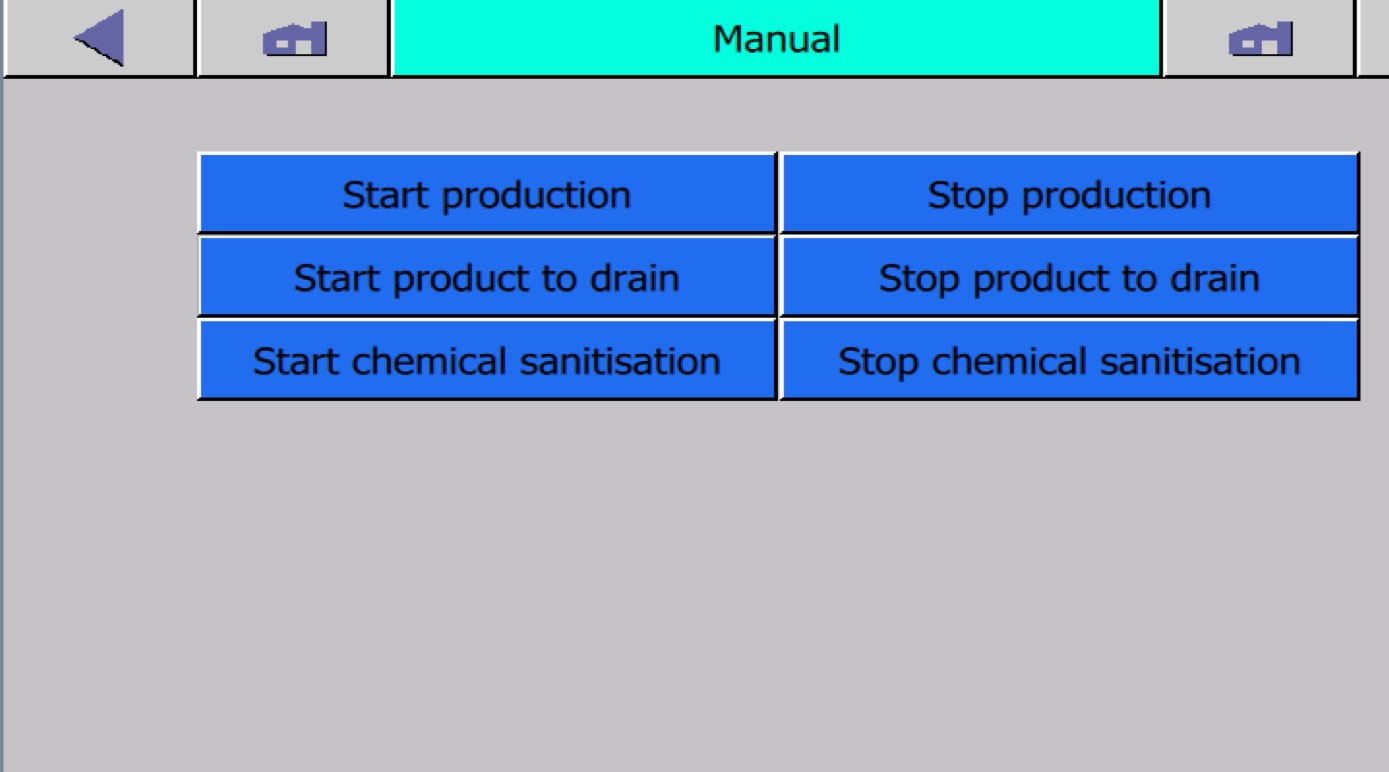

The Operator Panel (HMI) is located on the electrical cabinet door. This Siemens KTP900 is a 9’’ graphic TFT color display which features a USB interface, 8 function keys and a USB storage device to store historical trending and data. The CEDI operation is displayed as clear and well-arranged P&ID, all relevant screens with associated parameters are easily accessible and user-friendly. The HMI visualizes the control and monitoring performed by the PLC. This Siemens S7-1215 PLC also includes ethernet communication for optional connection to a master PLC or DCS system.

The electrical cabinet is an IP54 rated, ventilated and lockable cabinet which accommodates the power supply, PLC and all electrical controls and connections. The Main Power switch and CEDI system CE plate are located on the electrical cabinet. In case ambient temperature is >35 °C additional air-conditioning can be installed optionally.

Performance & Dimensions and weight

PLC / HMI interfaces

Optional System Components

CIP connections

Automatic PTT and PTD valves

Experience, expertise and attention

We believe there are only a few companies in the world to rival what we do.

Thanks to our extensive experience in EDI solutions for power, pharmaceuticals, hemodialysis, petrochemicals and microelectronics applications, we developed essential insights into the technology and how it meets specific requirements ‘in the field’. This is reflected in the quality of training, service and validation we provide. So why not contact us? Our advice is free!